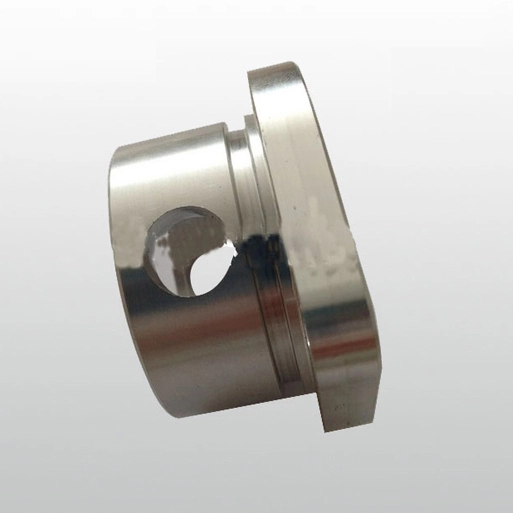

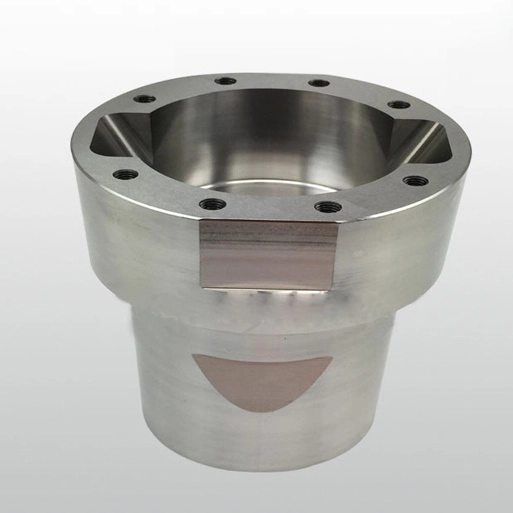

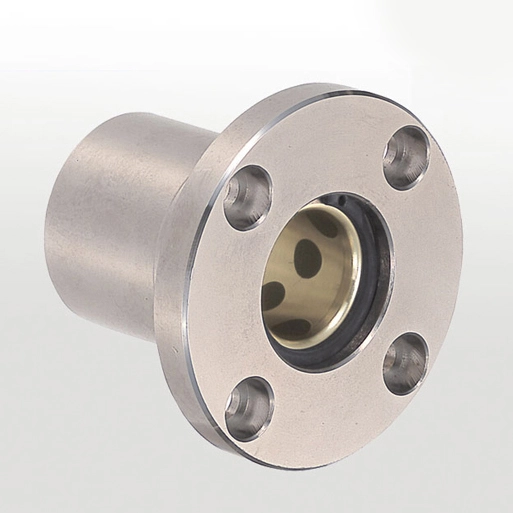

Gate Sleeves / Ejector Sleeves / Runner Sleeves / Mold Inserts / Rotation Prevention Sleeves

Hardness: HRC48-52

Common Materials: S136, 718H, 738H, H18

Description

Gate Sleeves: Gate sleeves play a crucial role in the molding process of medical devices. They control the flow of material into the mold, ensuring precise and controlled injection. These gate sleeves are engineered to maintain the integrity of the molded components.

Ejector Sleeves: Ejector sleeves are essential components within molds used for medical device production. They facilitate the ejection of finished products from the mold, ensuring efficient and smooth removal of components without damage.

Runner Sleeves: Runner sleeves are key elements in the mold system. They manage the flow of material from the injection point to the mold cavities. These sleeves are meticulously designed to minimize waste and ensure even distribution.

Mold Inserts: Mold inserts are critical components used for shaping and forming medical device parts. They are engineered to meet exacting standards, ensuring the precision and consistency of the final products.

Rotation Prevention Sleeves: Rotation prevention sleeves are designed to ensure that medical device components maintain their intended orientation. They play a vital role in ensuring that devices operate correctly and safely.