Punch Dies Suppliers: A Comprehensive Guide to Choosing the Right Supplier

When it comes to punch dies, selecting the right supplier is critical to ensuring precision, durability, and consistent performance in your manufacturing processes. Punch dies are essential components in industries such as metal stamping, automotive, aerospace, and electronics, where precision tooling is required for high-quality results. The right punch die supplier can help improve efficiency, reduce downtime, and ultimately lead to higher production output.

Table of contents

In this guide, we will explore everything you need to know about punch die suppliers, the types of punch dies available, and the key factors to consider when selecting a supplier for your tooling needs.

Why Punch Dies Matter in Manufacturing

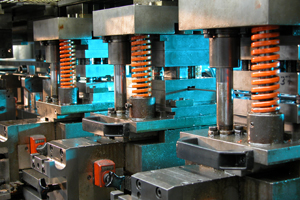

Punch dies are critical tools used in manufacturing processes that involve shaping, cutting, and forming metal or other materials. Whether you are working with sheet metal, aluminum, or more specialized materials, punch dies ensure precision and consistency in your operations. These tools are custom-designed to suit the specific dimensions and geometries required by your project.

From metal stamping to forming operations, punch dies are essential in applications ranging from simple hole punching to complex metal part manufacturing. Choosing the right supplier guarantees that your punch dies are crafted from high-quality materials and designed for long-lasting performance.

Types of Punch Dies Available from Suppliers

Round Punch Dies

Round punch dies are the most common and are used in applications where a circular cut is needed. Round punch dies are favored in metal stamping, blanking, and piercing operations, where precision and speed are required.

Shaped Punch Dies

For non-circular cuts, shaped punch dies are available in various geometries such as square, rectangular, hexagonal, or custom shapes. These dies are used for creating specific hole shapes or forming parts with complex designs.

Progressive Die Sets

Progressive dies allow for multiple operations to be performed in one stroke of the press. These dies are typically used in high-speed production environments where efficiency and accuracy are critical. Progressive die sets are an excellent choice for high-volume production as they streamline operations and reduce the need for manual interventions.

Compound Punch Dies

A compound die performs two or more cutting operations in one stroke, such as cutting the outer edge and punching a hole in the center of a part. These dies are ideal for creating intricate parts with precision, making them popular in industries like automotive and electronics manufacturing.

Custom Punch Dies

In addition to standard punch dies, many suppliers offer custom punch die solutions to meet specific customer requirements. Custom dies are designed to meet the exact dimensions, shapes, and material types needed for specialized manufacturing processes.

What to Look for in a Punch Die Supplier

Quality and Durability of Products

When choosing a punch die supplier, product quality is paramount. High-quality punch dies are made from durable materials such as tool steel, carbide, and high-speed steel (HSS). These materials offer excellent wear resistance and long tool life, ensuring your operations remain efficient over time.

Check whether the supplier offers heat-treated or coated punch dies, which can provide additional protection against wear and tear, increasing the overall lifespan of the tooling.

Customization Capabilities

Your manufacturing process may require punch dies with unique specifications. The best suppliers offer custom tooling solutions, enabling you to order punch dies designed to meet your exact application requirements. Custom options should include special geometries, coatings, and materials, allowing you to optimize your tooling for your production line.

Precision Manufacturing

Precision is key in the production of punch dies. Your supplier should use advanced manufacturing techniques such as CNC machining, wire EDM, and laser cutting to ensure that every punch die is made to the exact specifications. The precision of the die will directly impact the accuracy and quality of the final product.

Technical Support and Expertise

The best suppliers offer not just high-quality products but also extensive technical support. A knowledgeable team can assist with product selection, die design, and troubleshooting. Whether you need help choosing between different punch die materials or designing a complex custom die, a supplier with strong technical expertise can be a valuable resource.

Delivery and Lead Times

In today’s competitive manufacturing environment, lead times are critical. A reliable punch die supplier should provide accurate delivery times and have the capability to meet urgent orders without compromising on quality. Look for suppliers with efficient production processes and a track record of on-time deliveries.

Reputation and Reviews

Before selecting a supplier, check their reputation in the industry. Look for reviews, testimonials, and case studies that provide insights into the supplier’s reliability and quality. Reputable suppliers typically have a long history of serving leading industries and can offer references upon request.

Pricing and Value

While price is always a consideration, it should not be the sole factor in choosing a punch die supplier. High-quality punch dies may have a higher upfront cost, but they often last longer and provide better performance, ultimately offering greater value for your investment. Consider total cost of ownership (TCO) when evaluating suppliers, taking into account the quality, durability, and performance of the products they offer.

Top Punch Die Suppliers in the Market

Dayton Punch

Known for their wide selection of standard and custom punches, Dayton Punch is a leading supplier that offers high-quality punch dies suitable for a variety of industries. Dayton’s focus on precision manufacturing and innovation has made them a trusted name in the market.

Wilson Tool

Wilson Tool provides advanced punch die solutions, specializing in precision tooling for metal stamping and forming applications. Wilson Tool offers both standard and custom punch dies, including progressive dies and compound dies designed for high-performance operations.

Anchor Danly

With a comprehensive range of tooling components, Anchor Danly supplies high-quality punch dies for heavy-duty manufacturing processes. Their punch dies are known for their durability and precision, making them a top choice for industries that demand high-performance tooling.

Superior Die Set

Superior Die Set is another trusted punch die supplier that offers a variety of standard and custom dies. With a focus on customer-specific solutions, Superior Die Set provides high-precision punch dies for applications that require tight tolerances and long tool life.

MISUMI

MISUMI is a global supplier offering a diverse range of punch dies, die sets, and other precision tooling components. MISUMI is known for its customizable punch dies, allowing manufacturers to create tooling solutions tailored to their specific needs.

Gunri

Gunri Precision Hardware Co., Ltd., founded in 2006, is a top provider of high-precision parts, including nitrogen gas springs, mold components, and automation equipment parts. Certified with ISO9001:2015 and IATF16949:2016, Gunri exports to over 30 countries and offers OEM services across industries such as metal stamping, plastic molding, and semiconductor packaging.

Conclusion: Choose the Right Punch Die Supplier for Your Needs

When selecting a punch die supplier, it’s important to prioritize quality, customization options, precision, and technical support. By choosing a reputable supplier that offers durable, high-performance punch dies, you can ensure the success and efficiency of your manufacturing operations.

Take the time to evaluate potential suppliers based on their product offerings, manufacturing capabilities, and customer reviews. A reliable punch die supplier will not only provide you with the tools you need but also support your business in achieving its production goals.