Punch Pumping – The Overlooked Problem That Can Damage Your Punching Tools

In metal stamping, toolmakers and operators are usually focused on wear, alignment, and material feed. But there’s another, less visible issue that can quietly shorten tool life: punch pumping.

What Is Punch Pumping?

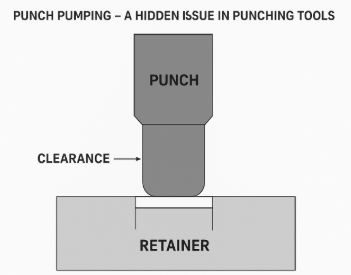

Punch pumping refers to micro-movements of the punch inside the retainer during each stroke. Even though the punch appears secure, small axial shifts can occur under load, especially during high-speed or high-load operations. Over time, these movements can cause significant damage.

Why Does It Happen?

One of the most common root causes is incorrect punch head thickness relative to the counterbore depth in the retainer. If the punch head does not fully seat against the counterbore surface, a gap or clearance is created. This clearance allows the punch to move slightly up and down with every press stroke—resulting in the pumping effect.

Consequences of Punch Pumping

If left unchecked, punch pumping can lead to:

- Mechanical damage to retainer walls due to repeated impact loading.

- Accelerated punch wear as the tool faces unintended stresses.

- Punch breakage in severe cases, especially in hard materials or high-tonnage applications.

Where Is It Most Common?

Punch pumping is most frequently seen in:

- High-load stamping operations where impact forces are substantial.

- High-speed presses where small movements are amplified by frequency.

- Situations where punch head fitment is not properly verified during setup or maintenance.

Preventing Punch Pumping

- Always measure and confirm punch head thickness against the retainer’s counterbore depth.

- Use precision-ground components to ensure a tight, stable fit.

- Inspect seating surfaces for wear or deformation during regular maintenance.

By paying attention to punch fitment during assembly and using proper dimensional control, manufacturers can greatly reduce the risk of punch pumping—protecting both tool life and production efficiency.