Revolutionizing the Automation Sector with Plastic Ball Cages

Introduction:

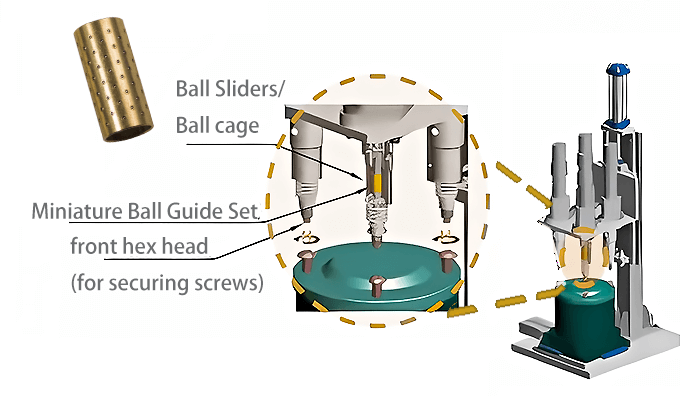

The automation sector is advancing at a rapid pace, with industries embracing innovative solutions to optimize efficiency and productivity. In this ever-evolving landscape, one component that has gained significant attention is the plastic ball cage. Crafted from polyoxymethylene (POM) resin and equipped with steel balls, these lightweight and durable components have revolutionized the world of automation.

I. The Power of Plastic Ball Cages:

Plastic ball cages have emerged as a game-changer in automation due to their exceptional properties. Let’s delve into what makes them a preferred choice:

Lightweight Marvels:

The use of plastic in these ball cages offers a lightweight solution without compromising strength. This reduction in weight allows for higher acceleration rates, a crucial factor in automation where speed matters.

Superior Performance:

Plastic ball cages excel in trial runs, ensuring smooth and uninterrupted operations. This reliability is paramount in automation systems that require consistent and flawless performance.

Unmatched Smoothness:

The precision engineering of plastic ball cages results in superior smoothness. This attribute minimizes friction, reducing wear and tear while maintaining efficiency.

II. Custom Solutions by Gunri:

At the forefront of innovation in automation components, Gunri specializes in offering customized solutions tailored to the unique needs of different industries. Here’s why Gunri’s offerings stand out:

Beyond Standardization:

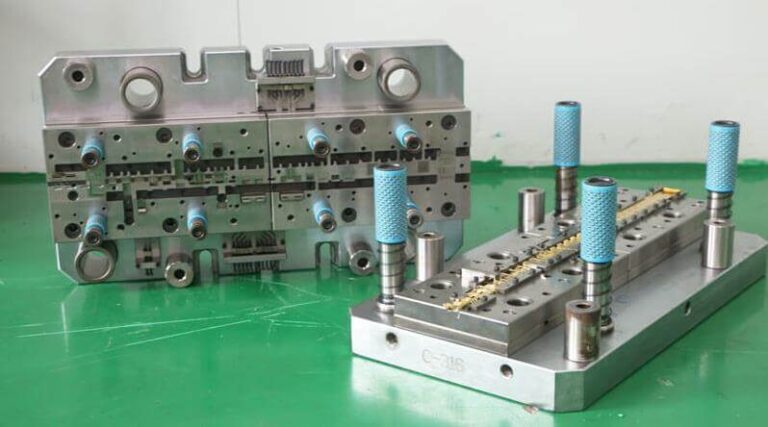

Gunri goes beyond catalog standards, providing options for sizes and designs that are customized to meet specific requirements. This flexibility is vital as automation applications can vary significantly.

Customer-Centric Approach:

Every component is designed and manufactured according to customer specifications. This approach ensures that the solutions provided align perfectly with the automation system’s demands.

III. Applications in Automation:

The applications of plastic ball cages in the automation sector are diverse and promising. Let’s explore some key areas where these components are making a significant impact:

Robotics and Robotic Arms:

Plastic ball cages play a vital role in ensuring the smooth and precise movement of robotic arms. Their lightweight nature enables robots to carry out tasks swiftly and accurately.

Conveyor Systems:

Automation in manufacturing heavily relies on conveyor systems. Plastic ball cages contribute to the efficiency of these systems by reducing friction and facilitating the smooth movement of materials.

Linear Motion Systems:

Linear motion systems, essential in automation, benefit from the precision and reliability of plastic ball cages. They ensure that linear movements are executed with finesse.

Pick-and-Place Applications:

In pick-and-place applications, where items need to be accurately picked and positioned, plastic ball cages provide the necessary stability and precision.

High-Speed Machinery:

Automation often involves high-speed machinery. The lightweight plastic ball cages enable these machines to operate at top speeds without compromising accuracy.

Conclusion:

As automation continues to shape the future of various industries, the role of components like plastic ball cages cannot be overstated. Their lightweight design, exceptional performance, and adaptability to custom requirements make them a cornerstone of automation solutions.

Gunri’s commitment to delivering tailored, high-quality components ensures that automation systems can operate seamlessly, contributing to increased productivity and efficiency across the board. The fusion of innovation, precision engineering, and customization options positions plastic ball cages as a driving force in the ever-evolving world of automation.