Selecting the Ideal Injection Mold Structure

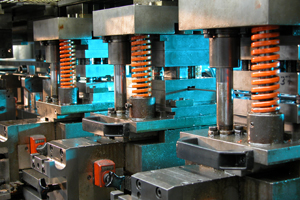

I. Designing the Injection Mold Based on Molding Equipment:

When designing an injection mold, it’s crucial to understand various injection molding machines’ performance and specifications. For instance, consider these specifications for injection machines:

Injection Capacity: Understand the machine’s injection capacity.

Mold Locking Pressure: Analyze the mold’s locking pressure requirements.

Injection Pressure: Determine the necessary injection pressure.

Mold Installation Dimensions: Consider the mold’s installation dimensions.

Ejector Mechanisms and Sizes: Assess ejector mechanisms and their sizes.

Nozzle Specifications: Examine nozzle hole diameter and nozzle radius.

Sprue Bush Positioning: Determine sprue bush positioning.

Mold Thickness: Establish the mold’s maximum and minimum thickness.

Template Stroke: Consider the template stroke.

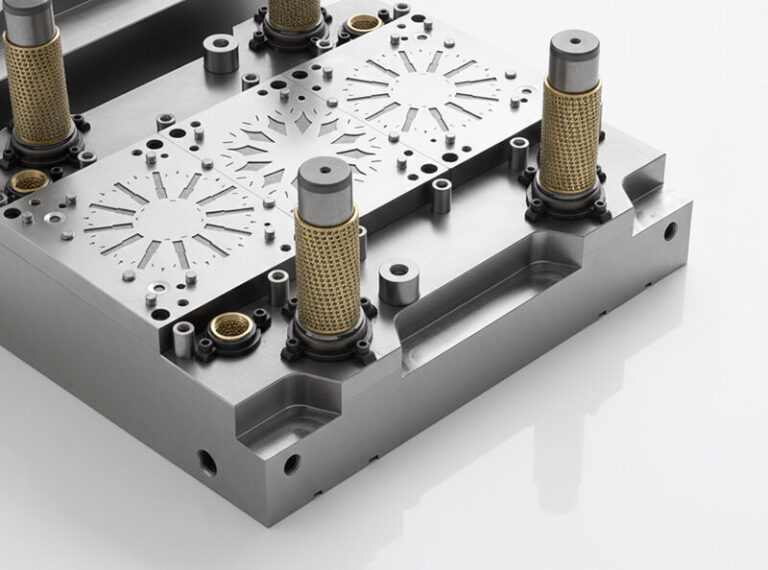

II. Determining the Injection Mold Structure:

Several factors influence the structure of an injection mold and its various systems, including:

Cavity Arrangement: Align the number and arrangement of cavities with geometric characteristics, dimensional accuracy requirements, batch size, mold manufacturing complexity, and cost considerations.

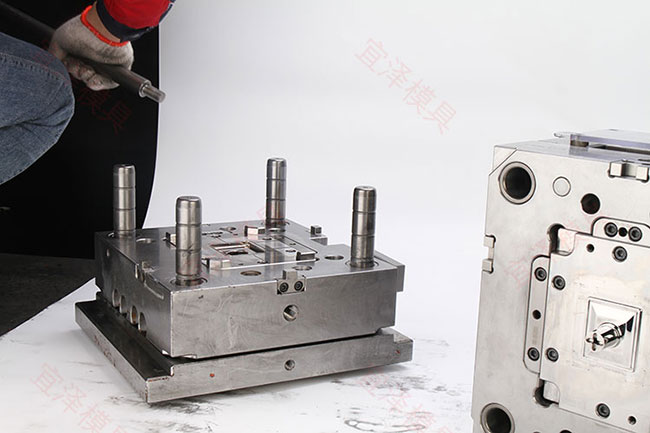

Parting Line: Optimize the parting line’s location for efficient mold processing, venting, demolding, and molding operations while ensuring superior surface quality.

Runner System: Define the shape, position, and size of the runner system, including main runners, sub-runners, and gates, as well as the venting system’s method, position, and size.

Ejection Methods: Choose the appropriate ejection method, whether it’s ejector pins, ejector sleeves, push plates, or a combination. Also, decide on side-core processing methods and core-pulling methods.

Cooling and Heating Methods: Specify the cooling and heating methods, along with the shape and location of cooling and heating grooves and the installation positions of heating elements.

Component Dimensions: Determine the dimensions, external structure, and positions of all connecting, locating, and guiding components based on mold material and strength considerations.

Main Component Structures: Define the structural forms of primary molding components and structural elements.

Strength Considerations: Evaluate the strength of various mold parts and calculate working dimensions for molding components.

At Gunri, we understand the intricacies of injection mold design and are ready to provide you with high-quality plastic mold components. For all your plastic molding needs, contact us at milla@gunri.com.cn. We look forward to assisting you in achieving your plastic molding goals.