Slide Units vs. Slide Retainers: Making the Right Choice for Your Die Sets

In the dynamic world of die sets and stamping components, the choice between Slide Units and Slide Retainers can significantly impact the performance and efficiency of your operations. Manufacturers and engineers are continually seeking the ideal solution to meet their specific needs. In this comprehensive article, we will explore the differences and advantages of these two components, with a particular focus on the offerings of Gunri Mold, a trusted name in the industry.

Table of contents

Understanding the Role of Slide Units and Slide Retainers

Before we dive into the comparisons, it’s essential to understand the roles these components play within the realm of die sets and stamping components:

Slide Units:

Slide units are complete systems designed to facilitate linear motion within the die set. They usually include guide rails, bushings, and other components, ensuring precise and smooth movement. They are favored for their all-in-one nature and ease of installation.

Slide Retainers:

Slide retainers, on the other hand, are specific components used to retain and guide balls or rollers within the die set. They contribute to the precision and low-friction movement of the die components. Slide retainers are known for their adaptability and cost-effectiveness.

The Differences: Slide Units vs. Slide Retainers

Let’s delve into the distinctions between slide units and slide retainers, highlighting their unique advantages and use cases:

Slide Units:

1. Complete Systems for Linear Motion

- Advantage: Slide units offer a holistic solution for linear motion within the die set. They come ready with all necessary components, simplifying installation and maintenance.

- Use Case: Slide units are ideal when you require a comprehensive system for linear movement and don’t want to source individual components separately.

2. Enhanced Precision and Smoothness

- Advantage: Due to their integrated design, slide units often provide enhanced precision and exceptionally smooth movement, reducing the risk of deflection and inaccuracies.

- Use Case: Applications demanding the highest precision, such as precision machine tools or high-accuracy stamping operations, benefit from slide units.

3. Suitable for Complex Setups

- Advantage: Slide units are well-suited for complex die set configurations and applications that involve multi-axis movement.

- Use Case: Industries with intricate die sets, such as automotive manufacturing or aerospace, often prefer slide units for their adaptability.

Slide Retainers:

1. Cost-Effective and Versatile

- Advantage: Slide retainers are renowned for their cost-effectiveness. They allow for versatile configurations without breaking the bank.

- Use Case: For budget-conscious projects or applications where adaptability is crucial, slide retainers offer an economical solution.

2. Low Friction and Efficiency

- Advantage: Slide retainers excel in low friction, ensuring efficiency in movement. They are suitable for applications where energy efficiency and reduced wear are essential.

- Use Case: Industries such as consumer electronics or general manufacturing often opt for slide retainers to improve efficiency and longevity.

3. Ease of Maintenance and Replacement

- Advantage: Slide retainers are relatively easy to maintain and replace. Individual components can be swapped out without the need to replace the entire system.

- Use Case: Applications where downtime is costly or maintenance needs to be rapid and straightforward find slide retainers advantageous.

The Gunri Mold Advantage

When making the choice between slide units and slide retainers, it’s essential to partner with a reliable and reputable provider. Gunri Mold stands as a trusted name in the industry, with a commitment to offering high-quality die set components that meet the specific needs of manufacturers and engineers.

Affordability Without Compromise

Gunri Mold is recognized for its affordability, ensuring that quality die set components are accessible without breaking the bank. Their pricing structure aligns with the budgetary constraints of many projects.

Prompt Deliveries and Unwavering Reliability

In a competitive market, timely deliveries are non-negotiable. Gunri Mold assures its customers of prompt deliveries, ensuring that production schedules are met without disruption. Their responsive customer service ensures a smooth experience from inquiry to delivery.

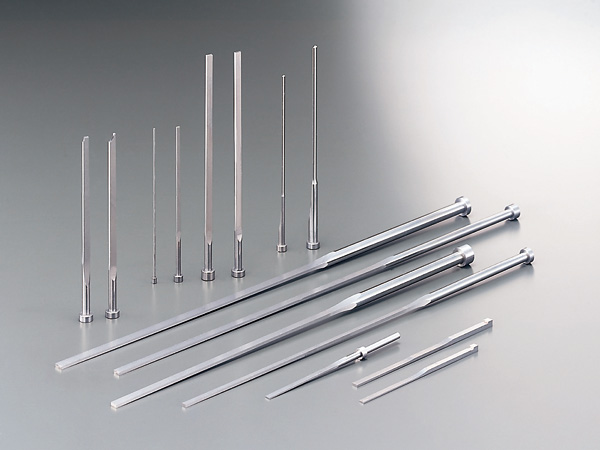

A Glimpse into Gunri Mold’s Authentic Workshop

Transparency is one of Gunri Mold’s core values. Their authentic workshop showcases the production of high-quality die set components, emphasizing their dedication to quality.

Conclusion: Choosing the Right Path for Your Die Sets

In conclusion, the choice between slide units and slide retainers largely hinges on the specific needs of your die set applications. Slide units offer all-in-one solutions, unparalleled precision, and suitability for complex setups. On the other hand, slide retainers are known for their cost-effectiveness, adaptability, low friction, and ease of maintenance.

To make the right choice for your die sets, trust Gunri Mold. With Gunri Mold, you can access high-quality die set components that align with your unique requirements. Your journey to optimizing your die sets begins here.

Make the smart choice for your die sets. Choose Gunri Mold for reliable, affordable, and high-quality components. Your path to enhanced die set performance starts here.