Unleashing the Superior Performance and Application Advantages of Million Guide

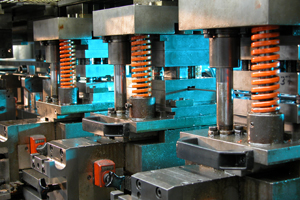

An Overview of the Core Highlights of Million Guide Million Guide has become a standout in industrial components, boasting remarkable advantages in accuracy, rigidity, and product lifespan. These features not only set it apart but also underscore its irreplaceable value…