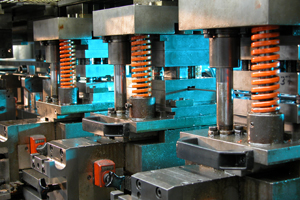

The Advantages of Using Nitrogen Gas Springs over Coil Springs in Dies

In the realm of die design and metal stamping, the choice of spring mechanism plays a crucial role in the efficiency, precision, and longevity of the tooling. While traditional coil springs have been a staple for decades, nitrogen gas springs are increasingly becoming the preferred option due to their numerous advantages. Let’s explore the key benefits of using nitrogen gas springs over their mechanical counterparts in die applications.

Consistent Force Application Throughout the Stroke

One of the most significant advantages of nitrogen gas springs is their ability to provide a near-constant force throughout their entire stroke. Unlike coil springs, where the force increases proportionally with compression, nitrogen gas springs deliver a more uniform and predictable force. This consistency is crucial for achieving consistent stamping results and preventing issues like material wrinkling or cracking.

Adjustable Force for Enhanced Flexibility

Nitrogen gas springs offer unparalleled flexibility due to their adjustable force capability. By simply charging or discharging nitrogen gas, the force exerted by the spring can be easily modified to suit different materials, thicknesses, or stamping operations. This adjustability eliminates the need for multiple coil springs of varying strengths, simplifying die design and setup.

Significant Space Savings in Die Design

Compared to coil spring arrangements that can often be bulky and require considerable space, nitrogen gas springs are typically more compact for the same force output. This space-saving advantage allows for more streamlined die designs, potentially reducing the overall size and weight of the tooling. This is particularly beneficial in complex progressive dies where space is often at a premium.

Extended Lifespan and Reduced Downtime

Nitrogen gas springs generally boast a longer service life compared to coil springs. Their sealed design protects the internal components from contamination, and the consistent force application reduces stress and wear on the spring itself. This extended lifespan translates to less frequent replacements and reduced downtime for die maintenance, ultimately increasing production efficiency.

Lower Maintenance Requirements

Due to their robust and sealed construction, nitrogen gas springs typically require less frequent maintenance than coil springs. Coil springs can be susceptible to fatigue, breakage, and loss of preload over time, necessitating regular inspection and replacement. Nitrogen gas springs, on the other hand, maintain their force characteristics for longer periods, reducing the need for frequent adjustments or replacements.

Higher Force Capability in a Smaller Footprint

For applications requiring high forces, nitrogen gas springs can often deliver greater force within a smaller physical space compared to traditional coil springs. This allows die designers to achieve the necessary force for demanding stamping operations without compromising the overall size or complexity of the die.

Improved Performance and Part Quality

The combination of consistent force, adjustability, and reduced vibration offered by nitrogen gas springs contributes to improved overall die performance and higher quality stamped parts. The predictable force application helps ensure consistent material flow and prevents issues like spring back, leading to more accurate and repeatable results.

Conclusion

The benefits of using nitrogen gas springs over traditional coil springs in dies are numerous and compelling. From consistent and adjustable force to space savings and extended lifespan, nitrogen gas springs offer significant advantages that contribute to improved efficiency, reduced costs, and enhanced part quality in metal stamping operations. For modern die design, nitrogen gas springs are often the superior choice for optimizing performance and productivity.