The Definitive Guide to Ball Guide Bushings for Die Sets

Table of contents

Elevating Precision and Efficiency with Ball Guide Bushings

In the realm of precision engineering and manufacturing, even the smallest details hold immense significance. When it comes to die sets, achieving unparalleled precision and efficiency takes center stage, and this is precisely where Ball Guide Bushings shine. These exceptional components play a pivotal role in ensuring flawless movement, reduced friction, and heightened accuracy in die set operations. This all-encompassing guide delves deep into the world of Ball Guide Bushings, meticulously exploring their features, advantages, applications, and vital considerations.

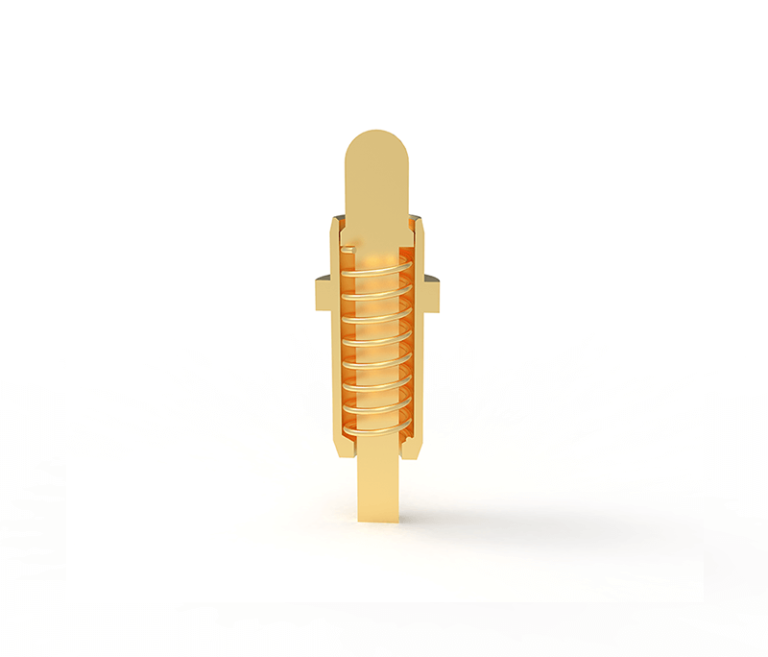

Understanding Ball Guide Bushings

Ball Guide Bushings are intricately designed precision components that facilitate seamless and accurate motion across various machinery applications. They form integral parts of die sets, widely employed in sectors ranging from metalworking to aerospace. The core function of these bushings lies in guiding the moving components within the die set, effectively minimizing friction and wear while upholding exceptional precision.

Key Attributes and Advantages

- Unmatched Precision: Ball Guide Bushings employ ball bearings to deliver precise and consistent linear motion. This culminates in heightened accuracy during die operations, translating to superior end-product quality.

- Friction Reduction: By integrating ball bearings, these bushings significantly mitigate friction in comparison to conventional sliding bushings. This not only prolongs the components’ lifespan but also contributes to the overall machinery efficiency.

- Seamless Motion: The ball bearings offer nearly frictionless movement, ensuring a seamlessly consistent motion even under substantial loads. This characteristic is pivotal for ensuring uniform results across diverse manufacturing processes.

- Remarkable Load Capacity: Despite their compact size, Ball Guide Bushings boast impressive load-bearing capabilities. This empowers them to handle substantial loads without compromising their performance.

- Minimal Maintenance: Owing to their intelligent design and minimized friction, Ball Guide Bushings demand minimal maintenance. This translates to reduced downtime and heightened productivity.

Applications of Ball Guide Bushings

Ball Guide Bushings find versatile applications in a wide spectrum of industries and machinery, where precision and efficiency are non-negotiable. A few notable applications include:

- Stamping Dies: Within the realm of metalworking, Ball Guide Bushings are pivotal in stamping dies, ensuring the precise alignment and movement of components, which ultimately leads to impeccably stamped parts.

- Injection Molding: In the domain of plastics, these bushings find their place in injection molding machines, guiding the moving parts to facilitate uniform and high-quality molded products.

- Automotive Manufacturing: The automotive assembly line relies heavily on Ball Guide Bushings, contributing to the precision and efficiency of various processes, right from chassis fabrication to engine assembly.

- Aerospace Engineering: The aerospace sector demands unparalleled precision, and Ball Guide Bushings play a pivotal role in manufacturing aircraft components, guaranteeing the highest levels of accuracy and safety.

Choosing the Right Ball Guide Bushings

Selecting the apt Ball Guide Bushings for your application warrants meticulous consideration. Here are key factors to factor in:

- Load Requirements: Thoroughly assess the expected load on the bushings to ascertain their ability to withstand forces without compromising performance.

- Precision Needs: Gauge the level of precision your application demands. Different bushing types offer varying degrees of accuracy.

- Environmental Conditions: Take into account the operating environment, encompassing factors such as temperature, humidity, and exposure to contaminants, to select bushings that can thrive in those conditions.

- Material Selection: Ball Guide Bushings are available in various materials including steel, bronze, and plastic. Opt for a material that aligns seamlessly with your application’s prerequisites.

- Installation and Maintenance: Prioritize bushings that are easy to install and require minimal maintenance, as this has a significant bearing on overall productivity.

Concluding Thoughts

In the intricate realm of precision engineering and manufacturing, Ball Guide Bushings emerge as irreplaceable components that elevate the efficiency, accuracy, and longevity of die set operations. Their unique ability to diminish friction, deliver seamless motion, and effortlessly handle substantial loads firmly establishes their role in diverse industries. Whether you’re immersed in metalworking, plastics, automotive, or aerospace, the impact of Ball Guide Bushings on your capacity to deliver exceptional outcomes cannot be overstated.

Elevate your precision engineering prowess with Ball Guide Bushings—where innovation converges with precision.

And remember, when it comes to sourcing high-precision mold components, Gunri stands ready to deliver. Our top-notch mold accessories are designed to significantly reduce mold wear, contributing to enhanced efficiency and longevity.