The Rise of New Energy Vehicles and the Evolving Role of Silicon Steel Laminations

Silicon Steel Laminations: The Unsung Hero of NEVs

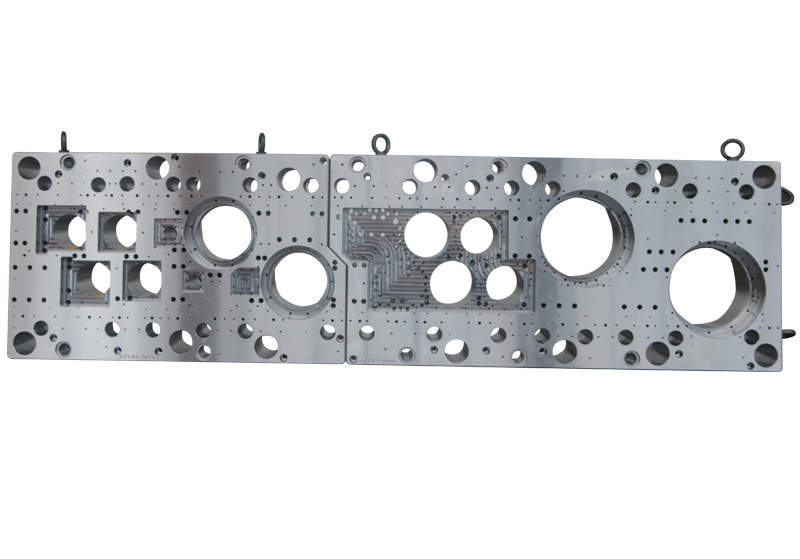

Though rarely in the spotlight, silicon steel laminations play a crucial role in the performance of new energy vehicles (NEVs). These thin, stamped sheets form the core of electric motors and transformers, directly influencing efficiency, power output, and durability.

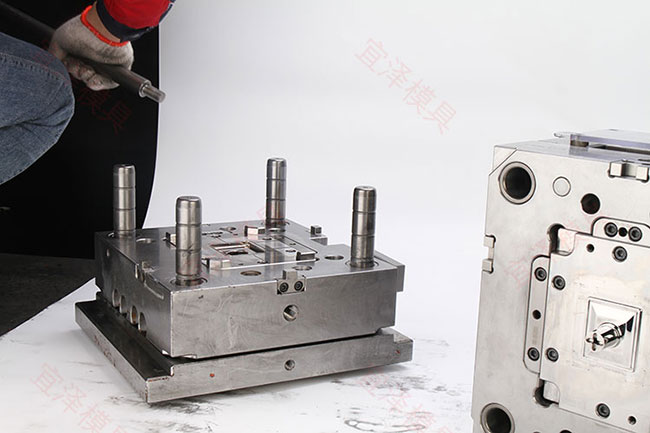

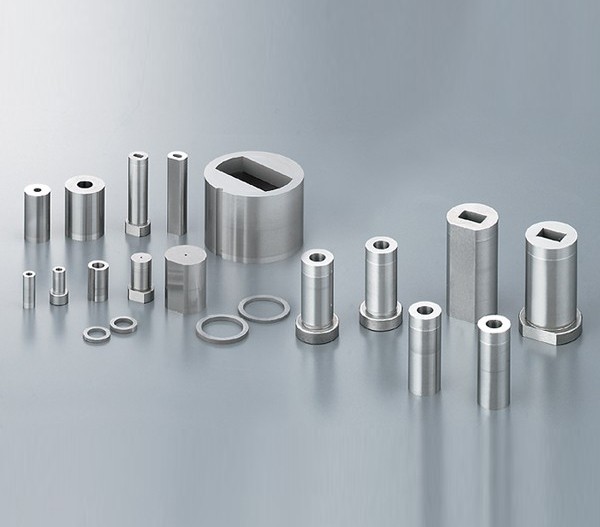

The precision of their production depends on advanced tooling systems, particularly roller guide post sets. These are critical components in stamping dies. Roller guide post sets ensure die rigidity, linear alignment, and smooth vertical movement. This enables consistent accuracy, even under high – speed intermittent operation and vibration. As the demand for NEVs rises, roller guide post sets are increasingly being adopted in silicon steel stamping dies to meet the stringent quality and durability requirements of mass production.

Enhancing Motor Performance

Silicon steel’s high magnetic permeability ensures a uniform magnetic flux distribution, which boosts the power density of motors. For example, Tesla’s latest motors use optimized laminations to improve efficiency and extend the vehicle’s range. Additionally, low hysteresis and iron losses minimize energy waste in the form of heat, enhancing the motor’s longevity.

BYD has reduced motor losses by 15% through advanced lamination designs. This has led to quieter operation and higher reliability, which are key features in luxury electric vehicles like BMW’s i – series. Behind these innovations is the precision of stamping processes, where roller guide post sets play a pivotal role. By maintaining die stability and minimizing deflection during high – speed stamping cycles, these components ensure that laminations meet micron – level tolerances. This is a non – negotiable standard for high – performance EV motors.

Supply Chain Challenges and Solutions

Raw Material Volatility

Silicon steel production relies on iron ore and specialty metals such as niobium and vanadium, whose prices have experienced significant fluctuations. In 2023, iron ore prices surged by over 20% due to supply disruptions in Brazil and Australia. Geopolitical risks further endanger the supply of rare metals. This situation necessitates strategic stockpiling and diversified sourcing.

Precision Tooling: A Hidden Bottleneck

Beyond raw materials, the production of high – precision stamping dies is becoming increasingly complex. Roller guide post sets, although a niche component, are emerging as a key element in quality control. If they fail to maintain alignment during continuous high – speed operation, it can lead to lamination edge burrs or thickness variations. These defects can compromise motor efficiency.

Leading suppliers such as Japan’s MISUMI and THK, along with China’s GUNRI (whose precision engineering capabilities have rapidly matured due to the growth of China’s NEV industry), are now collaborating with automakers. They are developing hardened, wear – resistant guide post systems capable of sustaining 1.5 million stamping cycles with a deviation of ≤5μm. This is a 30% improvement compared to traditional bushings.

Future Outlook: Synergy and Sustainability

Innovation and Integration

As NEVs demand higher efficiency, silicon steel producers are investing in advanced coatings, corrosion resistance, and thinner laminations. At the same time, stamping die technology is undergoing a quiet revolution. The integration of AI – powered predictive maintenance systems for roller guide post sets, which monitor real – time wear and thermal expansion, is reducing unplanned downtime by 40% in lamination plants. Such advancements ensure the scalability required to support the International Energy Agency’s (IEA) projection of 150 million EV motors by 2030.

Green Manufacturing

Sustainability is now of utmost importance. Recyclable laminations, energy – efficient production, and closed – loop systems are gaining popularity. Companies like Nippon Steel aim to cut CO₂ emissions by 30% by 2030 through hydrogen – based steelmaking, aligning with the automotive sector’s circular economy goals.

Even in tooling, eco – innovations are emerging. Lubricant – free roller guide posts with diamond – like carbon coatings now eliminate 90% of hydraulic oil usage in stamping lines. Self – lubricating polymer composites also extend service intervals, providing a double benefit in terms of cost and environmental impact.