The Top Five Advantages of Slide Bushings in Linear Motion Applications

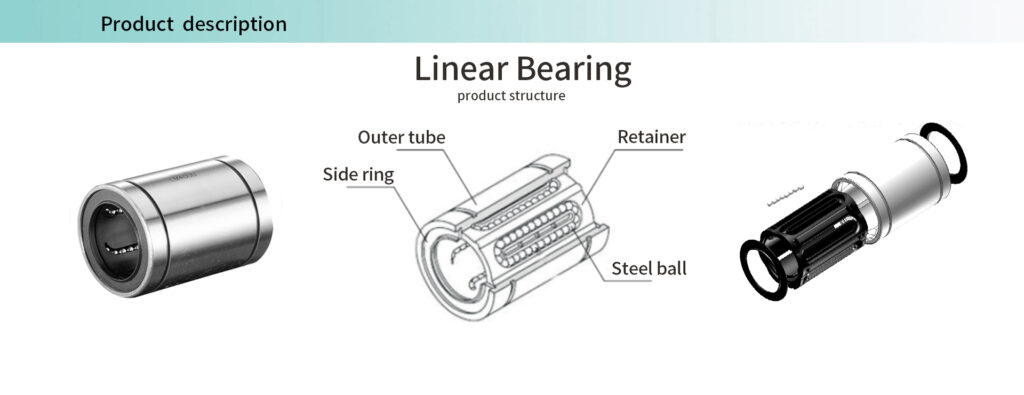

In the world of linear motion applications, slide bushings are indispensable components that offer a multitude of benefits. These precision-engineered devices are widely used for their ability to facilitate smooth and accurate linear movement. Below, we explore five compelling reasons why slide bushings are the preferred choice in linear motion applications:

1. Friction Reduction for Seamless Movement

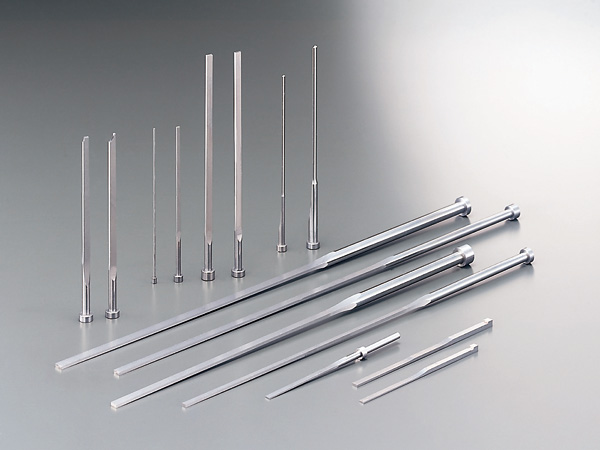

At the heart of slide bushings lies their ability to significantly reduce friction within a linear motion system. They consist of a precisely machined outer sleeve and a set of ball bearings or rollers, creating a low-friction environment for moving parts. This reduction in friction results in less wear and tear on components, ensuring longer service life and enhanced operational efficiency.

2. Unmatched Precision and Accuracy

Slide bushings are renowned for their exceptional precision and accuracy in linear motion. They offer tight tolerances, guaranteeing controlled and predictable movement. This level of precision is critical in applications that demand exact positioning or alignment, such as CNC machines, 3D printers, and robotic systems. Slide bushings deliver consistent, repeatable results, ensuring the utmost reliability.

3. Impressive Load-Carrying Capacity

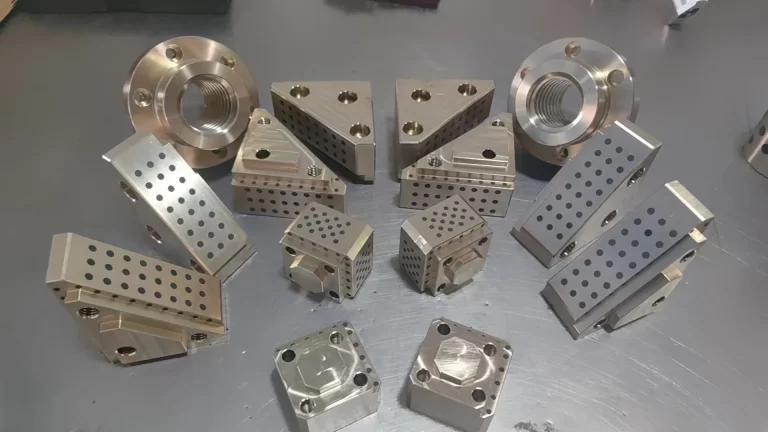

Engineered to handle substantial loads, slide bushings are well-suited for a wide range of applications. They can efficiently support both radial and axial loads, making them versatile for various industries. In scenarios where heavy loads need to be moved smoothly and reliably, such as in industrial machinery or conveyor systems, slide bushings shine with their high load-carrying capacity.

4. Low-Maintenance Operation

Slide bushings are known for their minimal maintenance requirements. Many types of slide bushings come equipped with seals or self-lubricating components that reduce the need for frequent maintenance or lubrication. This low-maintenance feature translates to reduced downtime and operational costs in industrial and manufacturing settings, making slide bushings an attractive choice.

5. Cost-Effective Solution for Linear Motion

In a world where efficiency and reliability matter, slide bushings offer a cost-effective solution. Their durability, low maintenance needs, and capability to withstand heavy loads contribute to an advantageous total cost of ownership. Industries spanning from automotive and aerospace to packaging find slide bushings to be a practical choice for achieving smooth, accurate, and efficient linear motion.

In summary, slide bushings are pivotal components in linear motion applications for their ability to reduce friction, deliver precision, handle heavy loads, operate with minimal maintenance, and provide cost-effective solutions. These advantages make slide bushings an integral choice for industries and applications that rely on flawless linear motion.