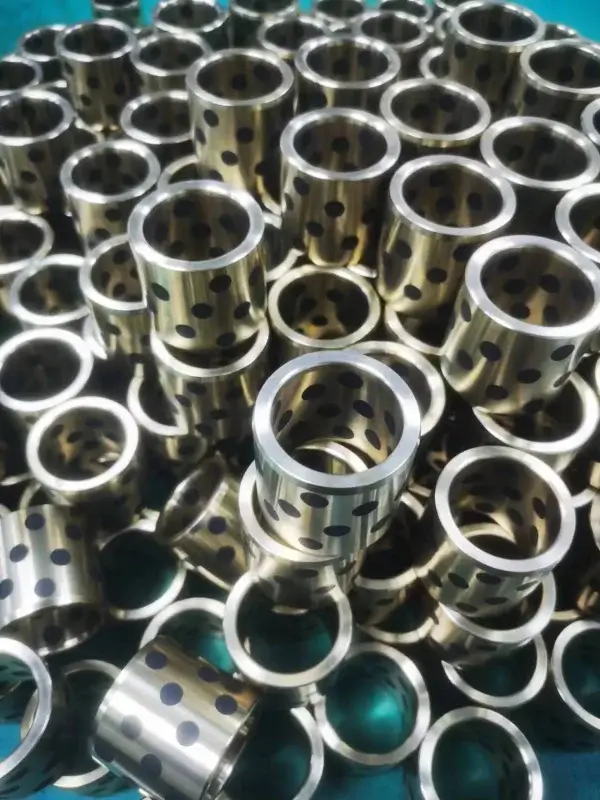

Three Methods of Installing Oil-Free

The installation methods for oil-free bearings or oil-free bushings generally involve three approaches: press-fit, interference fit by knocking, and assembly after shrink-fitting.

Most Commonly Used Methods:

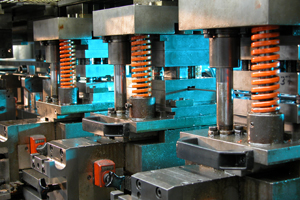

- Press-Fit Approach:

- Press the interference fit ring onto the shaft or into the bearing housing hole.

- Thermal Expansion or Contraction Approach:

- Expand the inner diameter of the oil-free bushing by heating it, or contract the outer diameter by cooling it. This allows for easy fitting onto the shaft or insertion into the housing hole.

Important Considerations:

- When using a press-fit method, mechanical force or hydraulic force is applied directly to the disassembled seat ring through a specialized device. It is strictly forbidden for the assembly or disassembly force to be transmitted through the rolling elements, as this could result in impressions on the raceway and rolling elements’ surfaces, increased noise, vibration, and potential damage.

- If using heating or cooling methods for assembly or disassembly, it is crucial to strictly control the temperature. The strength of the working surface of the bearing is influenced by the metal’s surface metallurgical structure. Excessive temperature can cause tempering effects, while too low a temperature can lead to surface embrittlement.

- Typically, the heating temperature should not exceed 100°C, and the cooling temperature should not go below -50°C. Additionally, uniform heating must be ensured.

Ensure these guidelines are followed to maintain the integrity and performance of oil-free bearings or bushings during installation and disassembly processes.