Tips for Extending the Lifespan of Mold Components

Maximizing the lifespan of your mold components is crucial for reducing downtime, lowering maintenance costs, and ensuring the consistent production of high-quality parts. By implementing proactive strategies and paying attention to key factors, you can significantly extend the service life of your valuable mold investments. Here are some essential tips, with a focus on how GUNRI products contribute to longevity:

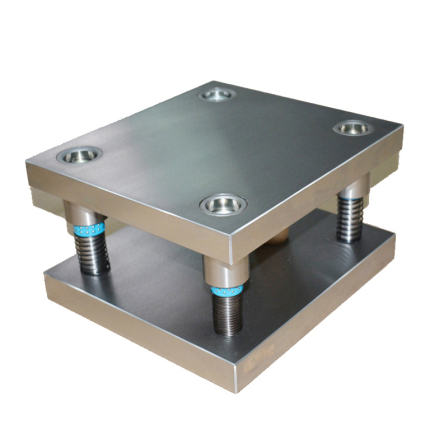

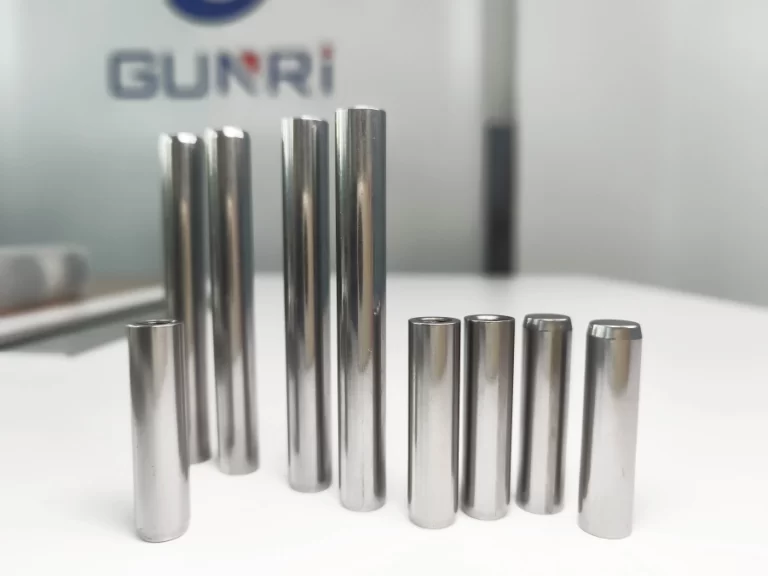

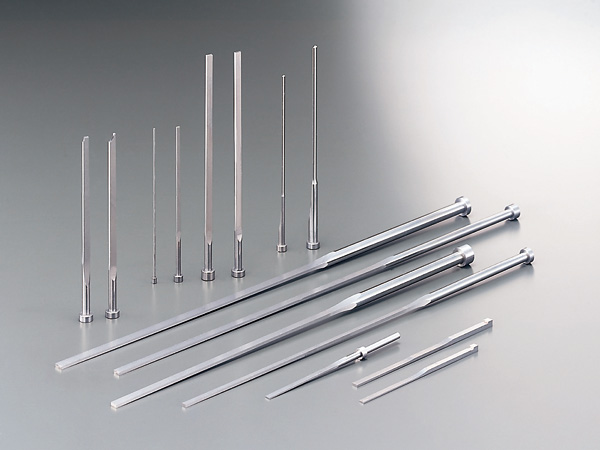

Focus on High-Quality Materials and Design

The foundation of long-lasting mold components lies in the quality of the materials used and the precision of the design. At GUNRI, we understand this critical aspect. Our guide pillars and bushings are manufactured from premium-grade materials, engineered for superior wear resistance and durability, ensuring they withstand the rigors of demanding production environments. Choosing high-quality components from the outset is the first step towards a longer mold lifespan.

Proper Lubrication is Key to Reducing Wear

Friction is a primary enemy of mold components. Implementing a robust lubrication schedule is vital for minimizing wear and tear. For components like ball bearing retainers, proper lubrication ensures smooth and efficient rolling motion, extending their operational life. GUNRI’s ball bearing retainers are designed to facilitate effective lubrication, contributing to their longevity and the overall performance of your mold. Similarly, regular lubrication of guide pillars and bushings prevents galling and reduces friction, maintaining their accuracy and extending their service life.

Regular and Thorough Cleaning Prevents Damage

Contaminants like dust, debris, and processing residues can accelerate wear and corrosion on mold components. Establishing a routine cleaning schedule is essential. Regularly cleaning your guide pillars and bushings will prevent the buildup of abrasive particles that can cause premature wear. Similarly, keeping nitrogen gas springs clean will help maintain the integrity of their seals and prevent malfunctions.

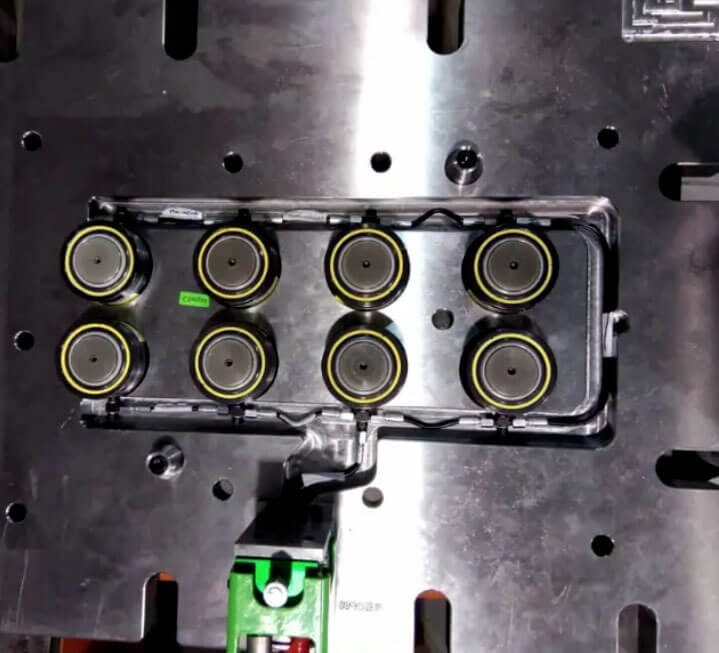

Implement a Preventative Maintenance Schedule

Proactive maintenance is far more cost-effective than reactive repairs. Regularly inspect all mold components for signs of wear, damage, or misalignment. This includes checking the pressure of your nitrogen gas springs. GUNRI’s nitrogen gas springs are designed for reliability, but regular checks ensure they maintain optimal performance and pressure, contributing to consistent molding operations and a longer lifespan. A well-defined maintenance schedule helps identify potential issues early, preventing more significant problems down the line.

Handle with Care and Avoid Overloading

Rough handling during mold assembly, disassembly, or storage can easily damage delicate components. Always follow proper handling procedures. Avoid exceeding the specified load limits for components like nitrogen gas springs. Overloading can lead to premature failure and compromise safety. GUNRI’s nitrogen gas springs are engineered for specific load capacities, and adhering to these limits is crucial for their longevity and safe operation.

Ensure Proper Alignment for Smooth Operation

Misaligned mold components can cause excessive friction and uneven wear. Precision-engineered guide pillars and bushings from GUNRI play a critical role in maintaining accurate alignment between mold halves. Ensuring proper alignment not only improves part quality but also significantly extends the lifespan of all interacting mold components.

Control Operating Temperatures to Prevent Material Degradation

Extreme operating temperatures can negatively impact the lifespan of various mold components, including seals in nitrogen gas springs and the materials used in guide bushings. Implementing measures to control and maintain optimal operating temperatures will help prevent material degradation and extend component life.

Proper Storage When Not in Use

When molds are not in production, proper storage is essential. Clean and dry the mold thoroughly and apply protective coatings to prevent corrosion, especially on steel components like guide pillars. Store molds in a controlled environment to minimize exposure to temperature fluctuations and humidity.

Regular Inspection of Nitrogen Gas Springs for Optimal Performance

Specifically for nitrogen gas springs, regular inspection is vital. Check for any signs of leakage, damage to the cylinder or rod, and ensure the pressure is within the recommended range. GUNRI’s high-quality nitrogen gas springs are built for durability, but routine checks will help identify any potential issues early, ensuring consistent performance and a longer service life.

Conclusion

Extending the lifespan of your mold components requires a combination of selecting high-quality parts, implementing diligent maintenance practices, and ensuring proper operation. By focusing on these key areas and choosing reliable components like those offered by GUNRI, you can significantly reduce your long-term tooling costs and maximize the efficiency of your molding operations.