Tooling Components Used in Stator Core Lamination Dies

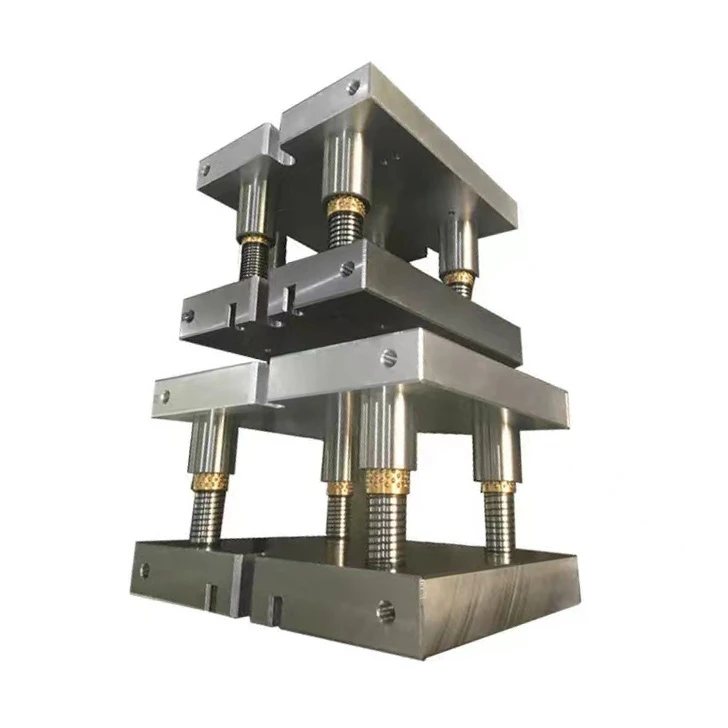

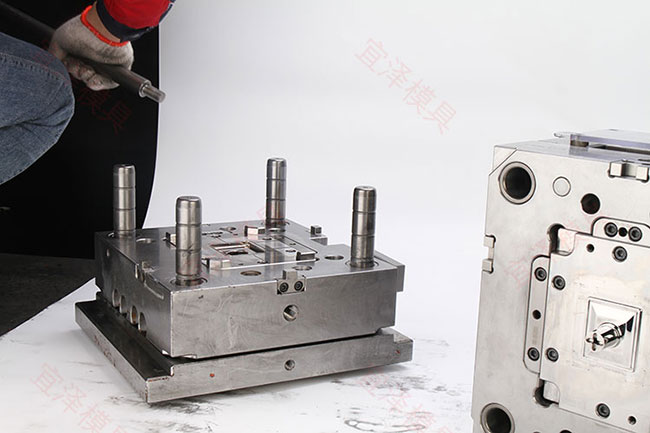

Stator core laminations are usually produced with high-speed progressive dies or compound dies. These dies operate at very high strokes per minute, which requires reliable and long-lasting precision components.

1. Cutting Components

- Punches – made of high-speed steels (M2, ASP23, etc.), with vacuum heat treatment and surface coating (TiN, TiCN) for extended life.

- Die Inserts – matching the punches with high wear resistance and hardness.

- Punch Retainers – ensuring secure and accurate punch positioning.

- Stripper Plates / Pressure Plates – preventing sheet sticking to the punch and maintaining smooth part release.

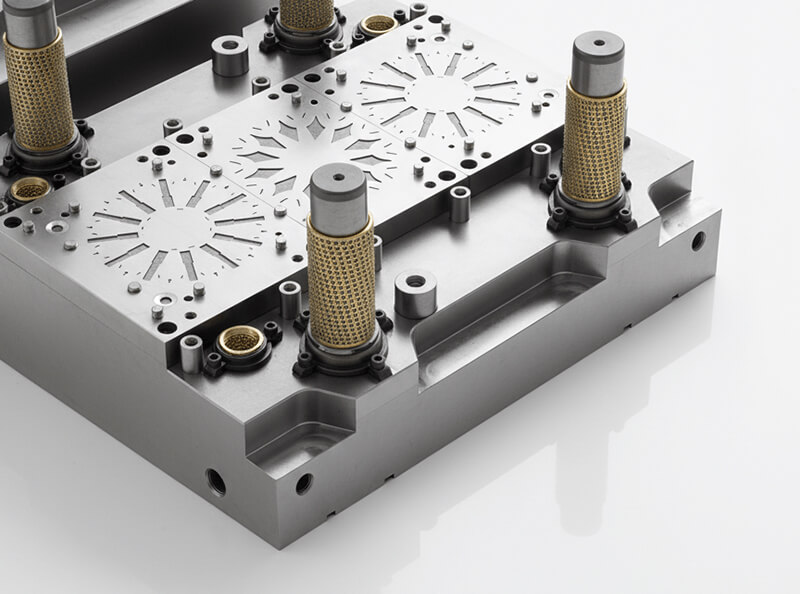

2. Guiding & Positioning

- Guide Posts & Guide Bushings – guaranteeing precise alignment between upper and lower die during high-speed stamping.

- Dowel Pins – for accurate assembly and repeatable positioning of die components.

- Pilot Pins – correcting strip position during progressive feeding.

3. Pressing & Stripping Elements

- Nitrogen Gas Springs or Coil Springs – providing uniform pressure and stable stripping force.

- Pressure Pads – securing silicon steel sheets and reducing burr formation.

4. Stacking & Material Handling

- Lamination Stacking Pins – ensuring consistent stacking of stator laminations.

- Vacuum Slug Retention Components – preventing slug rebound and tool jamming during high-speed operation.

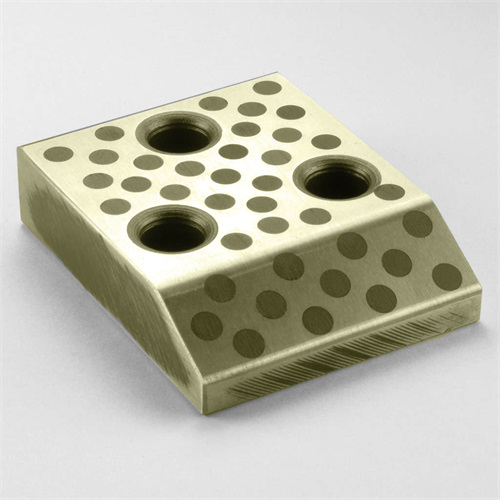

5. Wear & Protection Parts

- Wear Plates – installed in sliding areas to reduce friction and extend tool life.

- Stop Blocks – protecting the die from over-travel.

- Ejector Pins – pushing out slugs and scrap material reliably.

📌 If you need customized stamping die components, feel free to contact me. gunri is a professional manufacturer of precision die components and an OEM supplier for several international brands.