Types of Standard Guide Pins and Bushings

Introduction: Standard guide pins and bushings are foundational components in mold design and manufacturing. They play a pivotal role in ensuring precision and stability, particularly in applications where parts require accurate alignment. In this article, we will delve into various types of standard guide pins and bushings, discussing their characteristics, applications, and selection criteria.

1. Straight Guide Pins and Bushings:

- Characteristics: Straight guide pins have a cylindrical shape, offering linear guidance. They are often used in applications requiring straightforward linear movement.

- Applications: Commonly found in simple molds or fixtures where linear motion is essential for precise alignment.

- Selection Criteria: Straight guide pins are suitable for applications necessitating basic linear movement due to their simple design.

2. Shoulder Guide Pins and Bushings:

- Characteristics: Shoulder guide pins possess a stepped design with a larger diameter at the top, providing additional support and ensuring proper alignment.

- Applications: Ideal for applications requiring enhanced support and alignment accuracy, such as in multi-part molds or complex assemblies.

- Selection Criteria: Shoulder guide pins are chosen for applications where precise alignment is critical and additional support is needed.

3. Diamond Guide Pins and Bushings:

- Characteristics: Diamond guide pins have a unique diamond-shaped design that prevents rotation, making them suitable for applications where rotational movement must be restricted.

- Applications: Used in molds where parts need to be precisely oriented and rotation is undesirable, such as in medical device manufacturing.

- Selection Criteria: Diamond guide pins are selected when anti-rotation features are necessary for part alignment.

4. Ball Guide Bushings:

- Characteristics: Ball guide bushings consist of a linear ball bearing inside a cylindrical bushing, offering low friction and high-precision linear motion.

- Applications: Widely used in applications where smooth and precise linear motion is crucial, such as in CNC machinery.

- Selection Criteria: Ball guide bushings are preferred for high-precision applications demanding smooth linear movement and low friction.

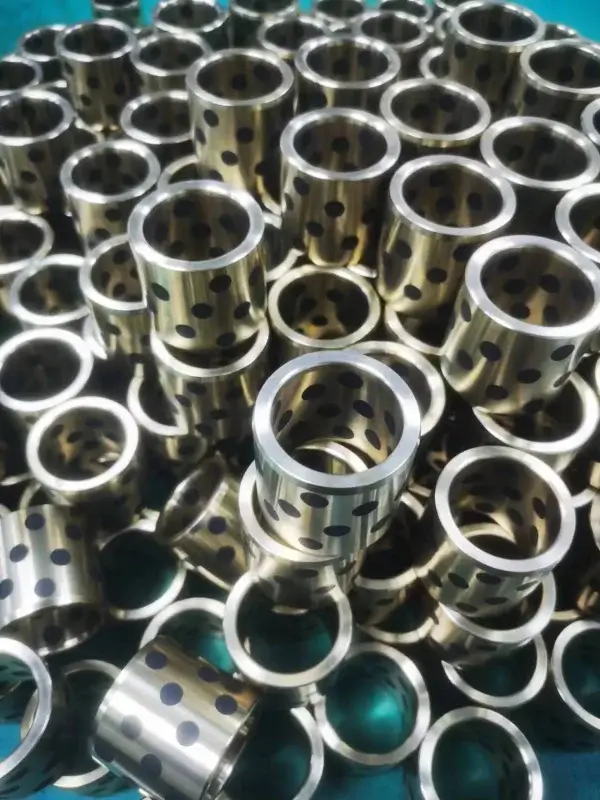

5. Self-Lubricating Guide Bushings:

- Characteristics: Self-lubricating guide bushings feature built-in lubrication reservoirs, reducing the need for external lubrication.

- Applications: Suitable for applications where maintenance-free operation is desired or where traditional lubrication is challenging.

- Selection Criteria: Self-lubricating guide bushings are chosen to minimize maintenance efforts and ensure consistent performance over time.

Conclusion: Selecting the appropriate standard guide pins and bushings is a critical aspect of mold design and manufacturing. Understanding the characteristics and applications of different guide pins and bushings is vital for achieving precise alignment and stability in various industrial processes. By considering the specific requirements of each application, manufacturers can choose the right type of guide pins and bushings to optimize performance and ensure the highest level of quality and accuracy in their products.