Understanding PCB Flying Probe Tests: Technology and Applications

In the world of electronics manufacturing, ensuring the quality and reliability of printed circuit boards (PCBs) is paramount. To achieve this, various testing methods are employed to detect electrical and circuit problems, guarantee the performance of final products, minimize waste, and optimize safety. One of the most versatile and cost-effective testing methods is the PCB Flying Probe test (FPT). In this comprehensive guide, we will delve into what a PCB Flying Probe test is, its advantages, and how it operates, all supported by sound reasoning and evidence.

Table of contents

What is a PCB Flying Probe Test?

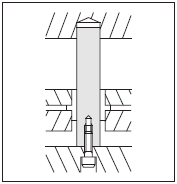

A PCB Flying Probe test, often referred to as FPT, is an automated testing system that employs a small number of precision probes to make contact with test points on a PCB. Unlike traditional bed-of-nails testing, which requires custom fixtures and can be time-consuming to set up, FPT uses high-precision needles that “fly” around the top and bottom of a PCB simultaneously, making electrical contact with test points based on a pre-programmed test routine.

Advantages of Flying Probe Tests

Before delving into the technical details of how FPT works, let’s explore why it has become a popular choice in the electronics manufacturing industry.

Detection of Electrical and Circuit Problems

Flying Probe tests are highly effective at identifying a wide range of electrical and circuit problems, including apertures, short circuits, capacitance and resistance issues, polarity errors, component absences, faulty soldering, and problems with component tolerances. These tests are crucial for ensuring the integrity of the PCB and the reliability of the final product.

Guaranteeing Reliability and Performance

By rigorously testing PCBs during the manufacturing process, FPT helps guarantee the reliability and performance of the final products. This is particularly important in industries where even a minor defect can lead to catastrophic failures.

Minimizing Waste and Product Recall

FPT plays a vital role in minimizing waste by catching defects early in the production process. This reduces the likelihood of producing defective products that would need to be recalled, which can be a costly and reputation-damaging endeavor.

How Does a Flying Probe Test Work?

Understanding how FPT operates is essential to appreciate its effectiveness and versatility. Let’s break down the process step by step:

1. Creating an FPT Test Program

The first step in conducting a Flying Probe test is to create a test program. This program defines the sequence of tests that the PCB will undergo. Typically, an offline computer is used for this purpose, equipped with specialized software for generating FPT test programs. The program requires input data, including Gerber files, Bill of Materials (BOM), and Electronic Computer-Aided Design (ECAD) files.

Alternatively, on the machine itself, a masterboard can be used to define values such as test points, component formats, offsets, and debugging parameters. This step is critical for tailoring the test program to the specific PCB being tested.

2. Uploading the Program

Once the FPT test program is created, it is uploaded to the Flying Probe tester. The PCB assembly that requires testing is then placed on a conveyor belt inside the tester. The conveyor transports the PCB to the area where the probe tests will be executed.

3. Application of Electrical and Power Test Signals

The heart of the Flying Probe test lies in the application of electrical and power test signals. The high-precision probes make contact with test points on the PCB, and electrical measurements are taken. These measurements are compared to the expected results based on the test program.

Any deviations from the expected results indicate a defect in the PCB, which could be related to a component failure, soldering issue, or circuit problem. These deviations are meticulously recorded and analyzed to pinpoint the exact nature of the defect.

Why is the Flying Probe Test Important?

The importance of the Flying Probe test cannot be overstated, especially in the early stages of product development and for low to medium volume production. Here are some key reasons why this type of test is crucial:

- Prototyping and Design Verification: During the prototyping phase, it is essential to evaluate and verify the design and performance of a product or project. The Flying Probe test provides rapid feedback on the integrity of the PCB design and helps identify issues that may require revision.

- Time-to-Market Reduction: In today’s competitive electronics industry, time-to-market is a critical factor. The ability to conduct a test within a matter of days or even hours, depending on the complexity of the PCB, accelerates the product development process.

- High Test Coverage: Flying Probe tests offer high test coverage, ensuring that a wide range of potential defects are identified. This comprehensive testing approach enhances the reliability of the final product.

In conclusion, the PCB Flying Probe test is a sophisticated and versatile testing method that plays a vital role in ensuring the quality, reliability, and performance of printed circuit boards. By employing precision probes, a well-defined test program, and meticulous analysis of test results, manufacturers can detect defects early in the production process, minimize waste, and optimize the safety of their products. The importance of this test cannot be understated, particularly in industries where precision and reliability are paramount.

At Gunri, we understand the critical role that test probes play in the electronics manufacturing process. We offer a wide range of high-quality PCB Test Probes, pH Current Probes, High Current Probes, Switch Probes, High-Frequency Probes, BGA Dual-Head Probes, POGO PIN Charging Spring Probes, Fixture Accessories, ICT Test Probes, German INGUN Probes, and Insulation Probes to meet your testing needs. Our products are designed to ensure accurate and reliable testing, helping you achieve the highest standards of quality and performance in your electronic products.

If you have any inquiries or require further information about our test probes and related products, please don’t hesitate to contact us. Our team of experts is ready to assist you in finding the right solutions for your testing requirements. Together, we can ensure the success of your electronics manufacturing projects.