Understanding Progressive Stamping Dies and Key Die Components

As the manufacturing industry continues to evolve, progressive stamping dies play a crucial role in the production process. This advanced molding technology not only enhances production efficiency but also improves product quality and consistency. This article will delve into the details of progressive stamping dies and their essential components, shedding light on their significance in modern manufacturing.

1. Introduction to Progressive Stamping Dies

Progressive stamping dies are highly efficient and precise manufacturing tools widely used in metal stamping processes. They employ a series of progressive impacts and deformation steps to gradually cut and shape metal materials, resulting in complex parts or components. This type of die design utilizes multiple stations, each performing different stamping or forming tasks, allowing the entire process to be completed in a single die run.

2. Advantages of Progressive Stamping Dies

2.1 Increased Production Efficiency

The multi-station design of progressive stamping dies allows simultaneous execution of multiple operations, significantly boosting production efficiency compared to traditional single-step stamping dies. This is particularly important for large-scale production or high-precision requirements.

2.2 Precision Forming

By employing a step-by-step stamping approach, progressive stamping dies can precisely control the metal material, ensuring the final product meets design specifications in terms of dimensions and shape. This is crucial for manufacturing that demands high levels of consistency.

2.3 Applicability to Complex Parts

The flexible design of progressive stamping dies makes them suitable for producing parts with complex shapes and high precision, expanding their application range.

3. Key Die Components

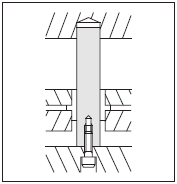

3.1 Die Base

The die base is the foundational component that supports and secures the die. Its quality directly influences the stability and precision of the die. A high-quality die base ensures that the die remains stable during high-speed operations, thereby improving production efficiency and die lifespan.

3.2 Punches and Die Blocks

Punches and die blocks are components directly involved in metal forming. The design and manufacturing quality of these components determine the surface quality and shape precision of the final product. Using advanced alloys and surface treatment techniques enhances the wear resistance and lifespan of punches and die blocks.

3.3 Transmission System

The transmission system powers the entire progressive stamping die operation, and its stability and precision are crucial for the die’s performance. Employing an efficient and low-noise transmission system enhances the die’s operational efficiency and production quality.

3.4 Automation Control System

Modern progressive stamping dies are often equipped with advanced automation control systems. These systems utilize precise sensors and control algorithms to monitor and adjust the die’s operation in real-time. This not only improves production stability but also makes the manufacturing process more intelligent and controllable.

Conclusion

The introduction of progressive stamping dies has brought about significant changes in modern manufacturing. Through thoughtful design and high-quality die components, manufacturers can fully leverage the advantages of progressive stamping dies, increasing production efficiency, reducing costs, and ensuring product quality and consistency. As technology continues to advance, progressive stamping dies will play an even more vital role in the manufacturing industry.