Unleashing the Power of Aluminium Ball Cages in the World of Die Sets

In the realm of die sets and stamping components, precision, efficiency, and durability are non-negotiable factors. Manufacturers and engineers continuously search for solutions that not only enhance the performance of their die sets but also maintain cost-effectiveness. Enter Aluminium Ball Cages, an innovative component that is revolutionizing the industry. In this comprehensive article, we will delve into the versatile applications of aluminium ball cages in the world of die sets, with a special focus on the offerings of Gunri Mold, a name synonymous with quality and affordability.

Table of contents

The Role of Aluminium Ball Cages in Die Sets

Before we delve into the numerous advantages of aluminium ball cages, it is essential to understand their role within the realm of die sets. These meticulously designed components serve as guides and retainers for balls or rollers within the die set, ensuring precision, smooth movement, and enhanced performance. Let’s explore why they are indispensable:

- Precision Engineering: Aluminium ball cages are engineered to perfection, providing unmatched precision and accuracy in die set operations. They play a pivotal role in achieving precise alignment and consistent results.

- Effortless Movement: These cages are renowned for their low friction properties, facilitating effortless movement within the die set. This attribute translates into energy savings and reduced wear and tear.

- Durability: Aluminium ball cages are built to last, ensuring prolonged tool life and minimal maintenance, which ultimately leads to significant cost savings.

The Remarkable Advantages of Aluminium Ball Cages

Let’s delve deeper into the specific advantages of incorporating aluminium ball cages into your die sets:

1. Precision Redefined

The hallmark feature of aluminium ball cages is their ability to deliver unparalleled precision. With precise alignment and movement, these cages ensure that your die sets produce accurate and consistent results, minimizing defects and rework. Your quest for precision ends here.

2. Efficiency on Overdrive

Aluminium ball cages are synonymous with low friction. This property translates into the smoothest possible movement of components within the die set. The result? Enhanced operational efficiency, reduced energy consumption, and minimized wear and tear. Efficiency has a new name: aluminium ball cages.

3. Versatility Across Industries

The versatility of aluminium ball cages cannot be overstated. Whether you are in the realm of cold punching molds, precision machine tools, or other precision-critical applications, these cages seamlessly integrate into diverse die set scenarios. Their adaptability across industries is truly remarkable.

4. Gunri Mold: Delivering Affordability Without Compromise

In an intensely competitive market, affordability is a paramount consideration. Gunri Mold understands this need and offers aluminium ball cages that strike the perfect balance between affordability and uncompromised quality. Gunri Mold ensures that you can access cost-effective solutions without sacrificing performance or durability.

5. Prompt Delivery and Unwavering Reliability

Gunri Mold has forged a reputation for unwavering commitment to customer satisfaction. With a promise of prompt deliveries, you can trust Gunri Mold to meet your production schedules without delay. Their responsive customer service ensures a seamless experience from inquiry to delivery.

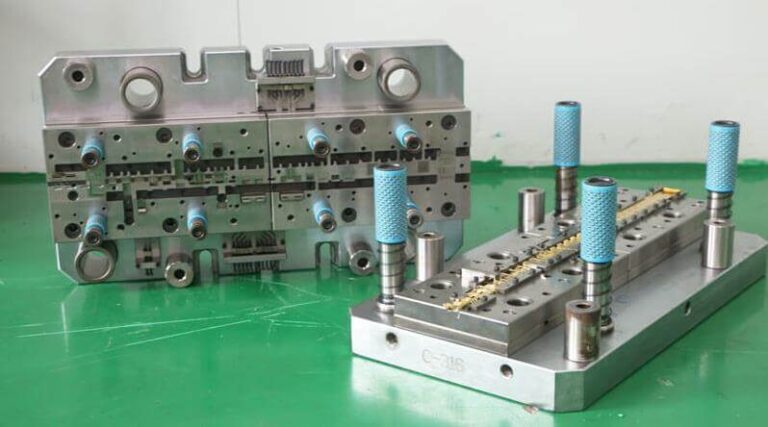

6. Gunri Mold’s Authentic Workshop: A Glimpse Inside

Transparency is a core value at Gunri Mold. Their dedication to maintaining a genuine and efficient workspace in their authentic workshop speaks volumes about their commitment to quality. Witness for yourself where high-quality die set components come to life.

Shaping the Future of Die Sets with Aluminium Ball Cages

In conclusion, aluminium ball cages are a transformative force in the world of die sets. Their unmatched precision, efficiency, versatility, and Gunri Mold’s commitment to prompt deliveries and an authentic workshop experience make them the ultimate choice for elevating your die set performance.

For manufacturers and engineers seeking to optimize their die sets, aluminium ball cages are the solution. Contact Gunri Mold today to explore how these exceptional components can elevate your die set requirements. Whether it’s precision, efficiency, or cost-effectiveness you seek, aluminium ball cages are the key to unlocking your die set’s full potential.

Make the intelligent choice for your die sets. Choose Gunri Mold for reliable, affordable, and high-quality aluminium ball cages. Your journey to unparalleled die set performance begins here.