Unlocking Efficiency with Straight Ejector Pins: A Deep Dive into Their Role in Die Sets

In the realm of die sets and stamping components, precision, efficiency, and reliability are paramount. Manufacturers and engineers continually seek innovative solutions to optimize their die sets for enhanced performance and streamlined production. One such solution that plays a pivotal role is the Straight Ejector Pin. In this comprehensive article, we will explore the multifaceted benefits of utilizing straight ejector pins in die sets, with a special focus on the offerings of Gunri Mold, a distinguished leader in the industry.

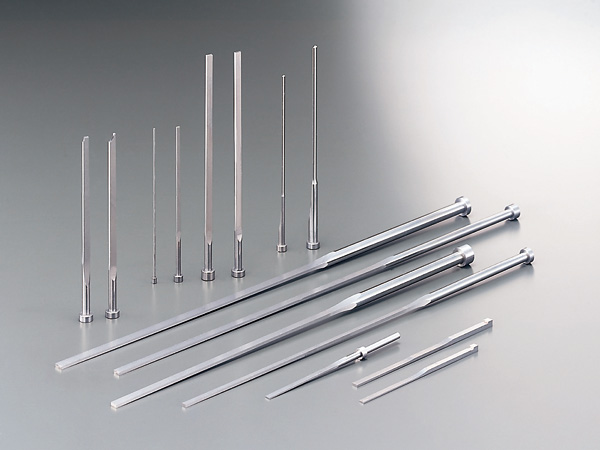

Decoding the Significance of Straight Ejector Pins

Before we delve into the remarkable advantages of straight ejector pins, it’s crucial to grasp their pivotal role within the world of die sets. These pins are designed to facilitate the ejection of components from the die, ensuring a smooth and efficient production process. Here’s why they are indispensable:

- Efficient Ejection: Straight ejector pins ensure that finished components are ejected promptly and accurately, reducing downtime and increasing productivity.

- Precise Alignment: They contribute to the precise alignment of components within the die, leading to consistent and high-quality outputs.

- Durability: Straight ejector pins are engineered for durability, ensuring prolonged tool life and minimal maintenance costs.

Unveiling the Pioneering Advantages of Straight Ejector Pins

Let’s delve into the specific advantages of integrating straight ejector pins into your die sets:

1. Efficiency Redefined

Straight ejector pins are synonymous with efficiency. They enable swift and precise ejection of components from the die, reducing cycle times and enhancing overall production efficiency. This translates into cost savings and improved throughput.

2. Versatility in Applications

The adaptability of straight ejector pins is remarkable. Whether your die sets are used in cold punching molds, precision machine tools, or other high-precision applications, these pins seamlessly integrate into various scenarios. They are designed to excel in diverse industries and settings.

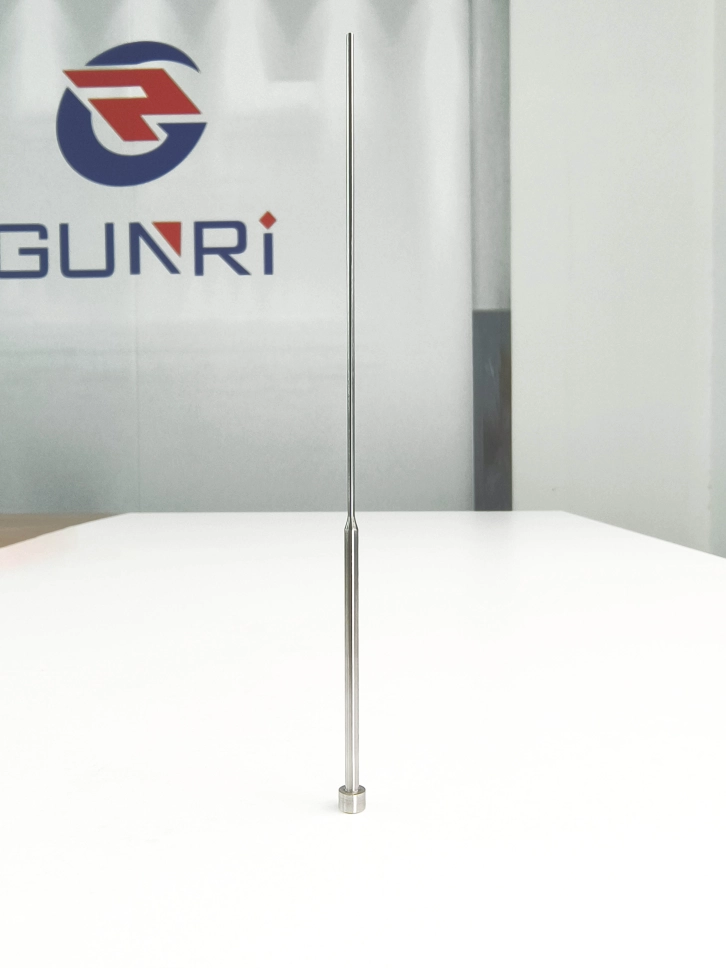

3. Gunri Mold’s Commitment to Affordability

In a competitive market, cost considerations are paramount. Gunri Mold understands this need and provides straight ejector pins that blend affordability with top-tier quality. You can rely on Gunri Mold to deliver cost-effective solutions without compromising on performance or durability.

4. Prompt Delivery and Reliability

Gunri Mold has earned a reputation for its unwavering commitment to customer satisfaction. With a promise of swift deliveries, you can trust Gunri Mold to meet your production schedules without delay. Their responsive customer service ensures a seamless experience from inquiry to delivery.

5. A Glimpse into Gunri Mold’s Authentic Workshop

Transparency is a core value at Gunri Mold. They take immense pride in their authentic workshop, where the production of high-quality die set components takes place. This dedication to maintaining a genuine and efficient workspace is a testament to their commitment to quality.

Realizing the Future of Die Sets with Straight Ejector Pins

In conclusion, straight ejector pins have emerged as a transformative force in the world of die sets. Their unrivaled efficiency, versatility, and Gunri Mold’s assurance of prompt deliveries and an authentic workshop experience make them the ideal choice for elevating your die set performance.

For manufacturers and engineers seeking to optimize their die sets, straight ejector pins are the solution. Contact Gunri Mold today to explore how these exceptional components can elevate your die set requirements. Whether it’s efficiency, precision, or cost-effectiveness you seek, straight ejector pins are the key to unlocking your die sets’ full potential.

Make the smart choice for your die sets. Choose Gunri Mold for reliable, affordable, and high-quality straight ejector pins. Your journey to unparalleled die set performance begins here.