What Are Automotive Line Nitrogen Gas Springs? (Definition, Functions, Applications)

In modern automotive stamping and forming processes, Automotive Line Nitrogen Gas Springs have become a critical component. Designed specifically for high-speed, high-volume automotive production lines, these gas springs provide stable force, long service life, and enhanced tool performance compared to traditional coil springs.

If you are in the automotive die-making or stamping industry, understanding the role of nitrogen gas springs can help you improve tool reliability, reduce downtime, and achieve better part quality.

Definition: What Are Automotive Line Nitrogen Gas Springs?

An Automotive Line Nitrogen Gas Spring is a high-pressure device filled with nitrogen gas, designed to deliver a strong, consistent, and controllable force inside automotive stamping dies.

Unlike mechanical coil springs, nitrogen gas springs store energy by compressing nitrogen gas. This allows them to provide 3–10 times more force in the same space and operate with millions of cycles without significant loss of performance.

They are widely used in automotive die sets for body panels, structural components, and other complex sheet-metal parts.

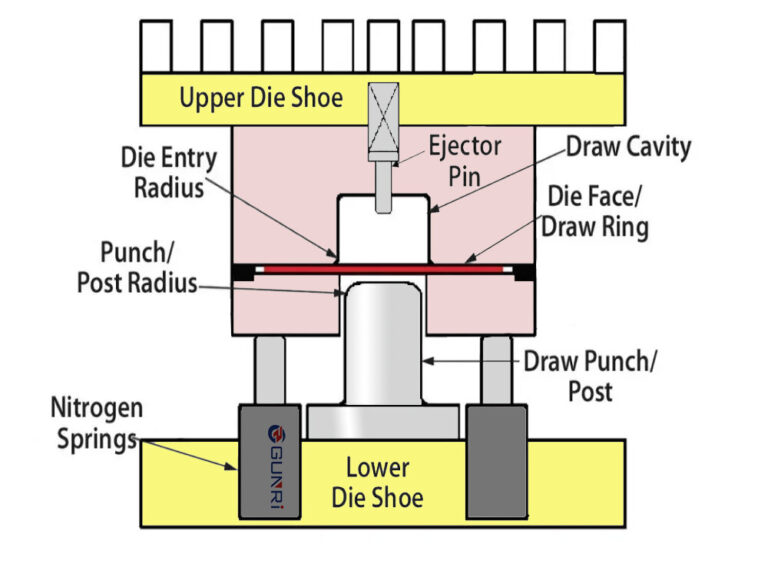

Key Functions in Automotive Stamping

- Provide Reliable Force

- Ensures consistent forming pressure during deep drawing, flanging, and bending.

- Maintains part accuracy even at press speeds of 300–1000 strokes per minute.

- Replace Traditional Springs or Cushions

- Offer a compact alternative to coil springs.

- Can substitute hydraulic or mechanical die cushions in many applications.

- Improve Tool Performance

- Reduce tool wear and spring fatigue.

- Provide adjustable pressure (typically 150–200 bar).

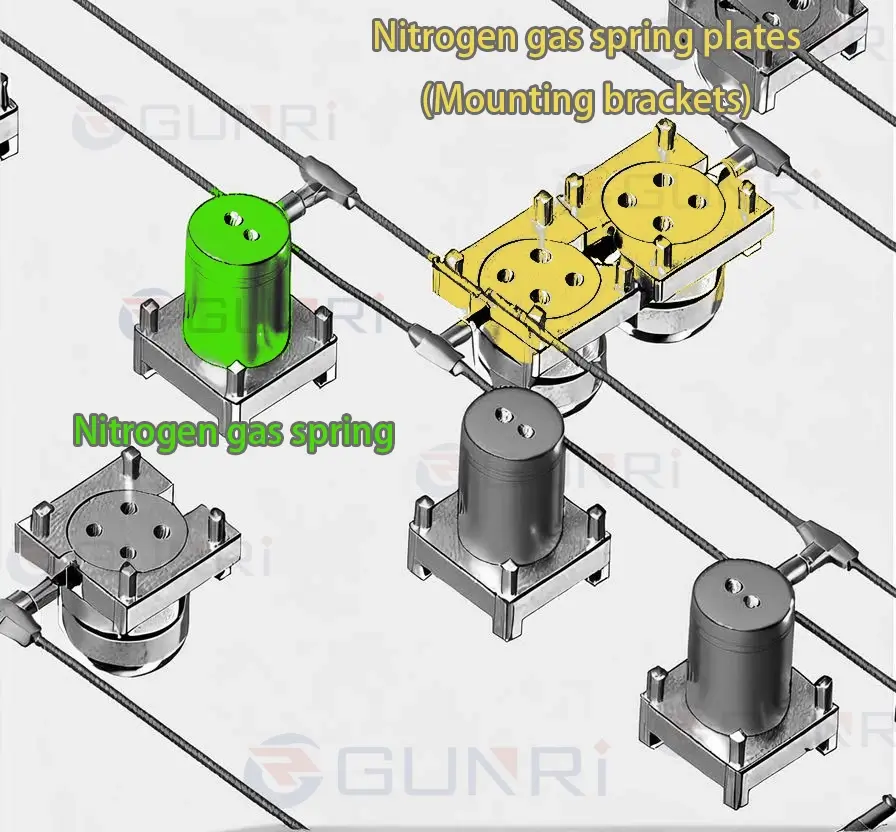

- Enable System Integration

- Can be connected via piping or manifolds for large automotive dies.

- Simplifies force distribution across multiple tool areas.

Applications in the Automotive Industry

Automotive Line Nitrogen Gas Springs are most commonly applied in:

- Body Panel Stamping

Hood, door, fender, trunk lid, and roof panel dies rely on nitrogen gas springs for uniform forming. - Deep Drawing Operations

Provides the necessary counterforce to avoid wrinkles and cracks in large sheet-metal parts. - Piercing and Trimming

Ensures accurate stripping and ejection of scrap, improving tool safety. - Large-Scale System Integration

Multiple gas springs are linked in a manifold system for complex dies in high-speed automotive production lines.

Advantages Over Traditional Springs

- Higher force density: More force in a smaller space.

- Longer service life: Millions of cycles with minimal maintenance.

- Consistent performance: Stable force output over time.

- Safety features: Built-in overpressure and anti-ejection systems.

- Cost efficiency: Lower downtime, fewer replacements, and higher tool productivity.

Conclusion

Automotive Line Nitrogen Gas Springs are no longer optional in modern automotive stamping—they are essential. By delivering reliable force, extended lifetime, and greater design flexibility, they help manufacturers achieve better part quality and higher production efficiency.

If you are looking for customized nitrogen gas springs for automotive dies, our factory specializes in high-quality gas springs with strict quality standards and competitive pricing.

Contact us today to discuss your requirements.