What Are Close Space Punches and Why They Matter in Precision Stamping

In precision metal stamping, accuracy and consistency are everything.

When the slot distance between holes becomes extremely small — such as in stator and rotor laminations or fine electronic terminals — traditional punches can’t fit or maintain durability.

That’s when close space punches become essential.

What Are Close Space Punches?

Close space punches are special stamping punches designed for tight-pitch or narrow spacing applications.

They are engineered to maintain stability and strength even when multiple holes are positioned very close together.

Typical applications include:

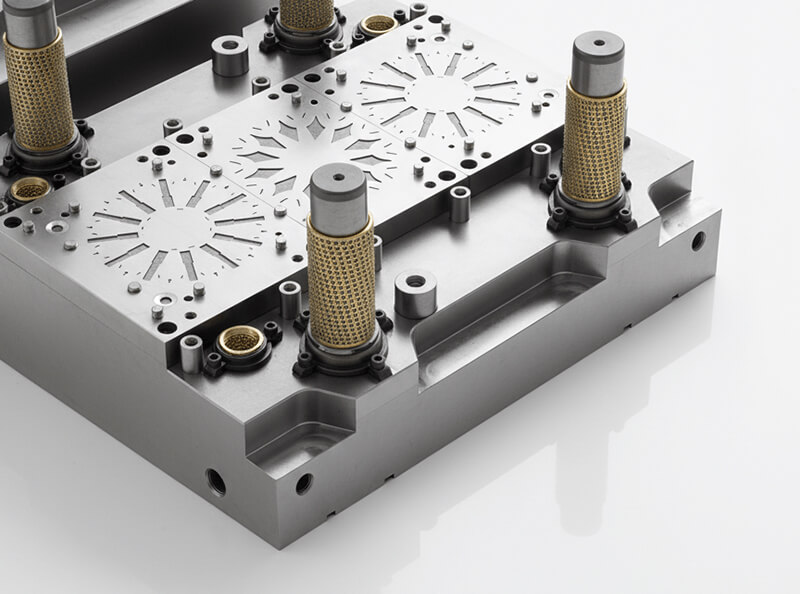

- Motor core stamping (stator and rotor laminations)

- Precision connectors and terminals

- Metal mesh or filter punching

Why Close Space Punches Are Important

In tight-spacing designs, even a tiny misalignment can cause tool breakage or poor part quality.

Close space punches solve this by offering:

- High dimensional accuracy — ensures uniform hole distance.

- Strong rigidity — prevents deformation during stamping.

- Optimized cooling and coating — extends tool life under continuous use.

- Smooth surface finish — reduces friction and improves part quality.

Material Options

Depending on your production requirements, close space punches can be made from:

- Tungsten Carbide – for high wear resistance

- HSS (High-Speed Steel) – for cost-effective performance

- Coated punches (TiN, TiCN, etc.) – to reduce friction and extend service life

Custom designs are often made according to your die layout, slot pitch, and material thickness.

Applications in Motor Core Stamping

In electric motor manufacturing, close space punches play a critical role in shaping stator and rotor laminations.

They allow manufacturers to achieve:

- High stacking accuracy

- Consistent slot geometry

- Longer die lifespan

These qualities directly affect motor efficiency and noise reduction, making close space punches a small but vital component in the entire production process.

Choosing the Right Close Space Punch Manufacturer

When selecting a supplier, consider:

- Material quality and heat treatment process

- Precision machining tolerance

- Coating and polishing capability

- Custom design support for your specific die layout

A reliable punch manufacturer will help you improve both production speed and accuracy, while reducing tool maintenance costs.

Conclusion

Close space punches are the key to achieving high-precision results in narrow-pitch stamping applications.

Whether you’re producing motor cores, electronic components, or fine metal parts, the right tooling solution will make all the difference.

Want to learn more or request a quote?

Contact us — we are a professional manufacturer of precision punches and mold components.