What are Guide Pillars and Why Are They Critical for Mold Accuracy?

In the intricate world of mold making and tooling, seemingly simple components often play a pivotal role in achieving high-quality results. Among these, guide pillars stand out as fundamental elements that directly impact the accuracy and overall performance of a mold. Let’s delve into what guide pillars are and why they are absolutely critical for ensuring precision in your molding operations.

What are Guide Pillars?

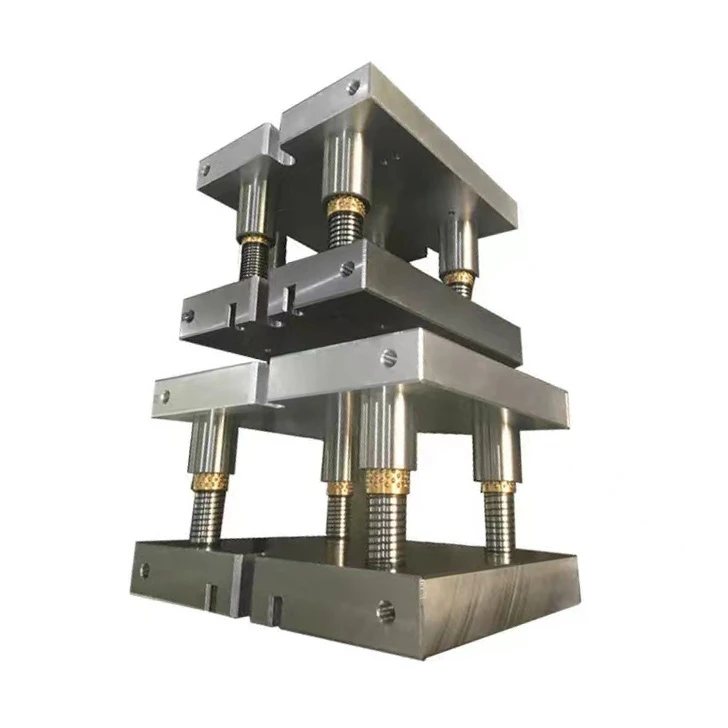

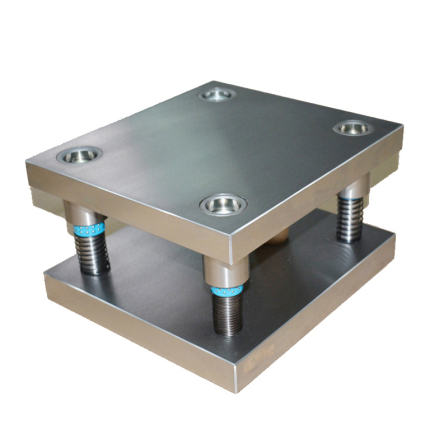

Guide pillars, also commonly referred to as guide pins or leader pins, are precisely machined cylindrical rods that are integral to the construction of most molds and dies. Typically made from hardened steel to withstand repeated use and high stresses, they are designed to work in conjunction with guide bushings (or guide sleeves) to ensure the perfect alignment of the mold halves.

The Primary Function: Ensuring Precise Mold Alignment

The core function of guide pillars is to guarantee the accurate and repeatable alignment of the two main halves of a mold – the core and the cavity – as they close. Think of them as precision dowels that guide the two parts together in a specific orientation. This precise alignment is absolutely essential for several reasons:

- Accurate Part Formation: When the mold halves are perfectly aligned, the molten material or workpiece fills the cavity correctly, resulting in parts that meet the intended design specifications and dimensions.

- Prevention of Mold Damage: Misalignment during mold closure can cause significant damage to the mold cavity, core, and other internal components, leading to costly repairs and downtime. Guide pillars prevent this by ensuring a controlled and precise closing motion.

Why is Mold Accuracy So Critical?

The accuracy of a mold directly translates to the quality and consistency of the parts it produces. Here’s why it’s so important:

- Dimensional Accuracy: Precise alignment ensures that the molded parts have the correct dimensions and tolerances, meeting the required specifications.

- Part Integrity: Proper alignment prevents issues like parting line mismatch, where the two halves of the molded part don’t meet correctly, resulting in weak or flawed products.

- Reduced Scrap Rate: Accurate molds produce consistent parts, significantly reducing the number of defective or unusable items.

- Extended Mold Life: By preventing damage from misalignment, guide pillars contribute to the overall longevity of the mold.

The Role of Guide Pillars in Maintaining Accuracy

Guide pillars, working in tandem with guide bushings, act as a reliable guiding system. As the mold closes:

- The guide pillars enter the corresponding guide bushings in the opposing mold half.

- The close fit between the pillar and the bushing ensures that the two halves are aligned with extreme precision before the mold fully closes and pressure is applied.

- This precise guidance prevents any lateral movement or shifting between the mold halves, guaranteeing accurate cavity registration.

Working in Tandem with Guide Bushings

It’s important to note that guide pillars don’t work in isolation. They are always paired with guide bushings. The guide bushings, typically made from wear-resistant materials like bronze or hardened steel, provide a precise bearing surface for the guide pillars to slide within. The tight tolerance between the pillar and the bushing is crucial for maintaining alignment and minimizing wear over repeated cycles.

The Importance of Quality Guide Pillars

Investing in high-quality guide pillars is essential for ensuring long-term mold accuracy and reliability. Factors like the material, hardness, and precision of the machining all play a significant role in the performance and lifespan of the guide pillars.

FAQ

What is the function of guide pillar?

The primary function of a guide pillar is to ensure precise and repeatable alignment between the two halves of a mold during each opening and closing cycle. This alignment is essential to maintain product dimensional accuracy and protect internal mold components from damage caused by misalignment.

What are the main elements of a mold?

A complete mold typically includes the following main elements:

- Core and cavity plates

- Guide pillars and guide bushings

- Ejector system (ejector pins, ejector plate, return pins)

- Cooling system (channels, connectors)

- Clamping plates

- Sprue bushing and runner system

Each component plays a role in forming the product, maintaining mold structure, or ensuring efficient operation during production cycles.

Which type of fit is used between guide pillar and guide bush?

A precision sliding fit is commonly used between the guide pillar and guide bush, typically within the H7/g6 or H7/h6 tolerance range. This tight fit ensures smooth movement while minimizing lateral clearance, which is critical for accurate alignment.

What are the components of a mold base?

The mold base includes the structural foundation and guiding components of the mold. Standard components are:

- Top clamping plate

- Cavity plate

- Core plate

- Bottom clamping plate

- Guide pillars and guide bushings

- Support plate or backing plate

- Ejector housing and plates

These parts support the mold inserts and ensure reliable mold function throughout production.

What is the main purpose of pillars?

In the context of molds, the main purpose of guide pillars is to direct the mold’s opening and closing motion. They control the relative position of the core and cavity, preventing misalignment that could lead to flash, parting line mismatch, or tooling damage.

What material is the guide pillar made of?

Guide pillars are usually made of hardened tool steel such as SUJ2, SKD11, or other wear-resistant alloy steels. These materials offer a balance of strength, toughness, and durability suitable for high-cycle operations.

Why are guide pillar and guide bush case hardened?

Case hardening is used to increase the surface hardness of the guide pillar and bush while maintaining a tough, ductile core. This allows the surfaces to resist wear during continuous sliding contact while avoiding brittle failure from impact or stress.

What is the hardness of a guide pillar?

The surface hardness of a guide pillar after heat treatment is typically in the range of HRC 58 to 62, which provides excellent resistance to wear and deformation under repeated operation.

What defines a guide bush?

A guide bush is a cylindrical sleeve designed to guide the movement of the guide pillar with high precision. It is usually made of hardened steel or bronze and may feature lubrication grooves or solid lubrication inserts to reduce friction and extend service life.

Conclusion

Guide pillars and guide bushings may seem like basic components, but they play an essential role in ensuring the precision, reliability, and longevity of mold systems. Whether you’re designing a new mold or maintaining an existing one, understanding the function and proper selection of guide pillars can greatly improve your production efficiency and product quality.

GUNRI provides high-precision, durable guide pillars and bushings tailored to meet your mold performance needs. Contact our team today to discuss custom specifications or explore our full range of mold components.