What is an ISO 10243 Spring?

ISO 10243 is an international standard that specifies the requirements for heavy-duty helical compression springs made from rectangular cross-section wire.

Im heutigen Gesundheitsdiskurs ist es wichtig, verschiedene Aspekte der männlichen Gesundheit zu betrachten. Viele Männer scheuen sich, darüber zu sprechen, was zu einem mangelnden Bewusstsein und Verständnis führt. Eine Lösung, die oft in Erwägung gezogen wird, ist die Möglichkeit, Medikamente online zu erwerben, wie beispielsweise, wenn man sich entscheidet, um zu “””kaufen stromectol online”””. Weitere Informationen und Unterstützung sind auf Plattformen erhältlich, wie beispielsweise unter “””””” für diejenigen, die Hilfe suchen.

These springs are typically used in applications requiring high load capacity within limited spaces, such as die-casting, mold-making, and heavy machinery.

Key Aspects of the Standard

- Materials: Types of steel used to manufacture these springs.

- Design and Dimensions: Sizes and tolerances of the springs, including outer diameter, free length, and wire cross-section.

- Load and Deflection Characteristics: Load ratings and corresponding deflection for springs of different sizes and types.

- Color Coding: System for identifying springs with different load ratings and deflection characteristics by color.

Materials

ISO 10243 specifies the use of high-strength alloy steels and carbon steels. Common types include:

Im heutigen Gesundheitsdiskurs ist es wichtig, verschiedene Aspekte der männlichen Gesundheit zu betrachten. Viele Männer scheuen sich, darüber zu sprechen, was zu einem mangelnden Bewusstsein und Verständnis führt. Eine Lösung, die oft in Erwägung gezogen wird, ist die Möglichkeit, Medikamente online zu erwerben, wie beispielsweise, wenn man sich entscheidet, um zu “””kaufen stromectol online”””. Weitere Informationen und Unterstützung sind auf Plattformen erhältlich, wie beispielsweise unter “””””” für diejenigen, die Hilfe suchen.

Chrome Vanadium Steel: Known for its excellent strength and elasticity, making it ideal for springs requiring high strength and fatigue life.

Chrome Silicon Steel: Offers good heat resistance and fatigue resistance, suitable for springs operating under high stress and high-temperature conditions.

Carbon Steel: High carbon steels like SAE 1070-1090 series, which have good strength and hardness, suitable for general industrial applications.

These materials undergo heat treatment and cold working processes to enhance their strength and durability, ensuring stable performance under high loads and frequent use.

Design and Dimensions

ISO 10243 specifies the sizes and tolerances for heavy-duty helical compression springs, covering aspects such as outer diameter, free length, and wire cross-section. Here are some specific size and tolerance requirements:

- Outer Diameter (OD):

- The tolerance for the outer diameter varies based on the size and application of the spring. Generally, the tolerance range is small to ensure the spring functions correctly within its designed space.

- For example, the outer diameter tolerance might range from ±0.1 mm to ±0.5 mm.

- Free Length:

- Free length is the length of the spring in its uncompressed state. Tolerances are determined based on the spring’s size and design requirements.

- Typically, the tolerance for free length ranges from ±1 mm to ±5 mm, depending on the total length of the spring.

- Wire Cross-Section:

- The wire cross-section is usually rectangular, with strict tolerance requirements for width and thickness to ensure the spring’s performance and consistency.

- For example, the tolerance for the wire cross-section might range from ±0.05 mm to ±0.2 mm, depending on the wire size.

Example dimensions for standard applications might be:

- Outer Diameter: 20 mm, tolerance ±0.3 mm

- Free Length: 100 mm, tolerance ±2 mm

- Wire Cross-Section: 3 mm x 5 mm, tolerance ±0.1 mm

Specific tolerances and size requirements should refer to the detailed provisions of ISO 10243 and the specific needs of the application environment.

Load and Deflection Characteristics

ISO 10243 specifies the load ratings for different sizes and types of heavy-duty helical compression springs. These ratings depend on the spring’s size, wire cross-section, free length, and material used. Here are some examples to illustrate the load ratings of different sizes and types of springs:

- Light Load Spring (Green):

- Outer Diameter: 20 mm

- Free Length: 50 mm

- Wire Cross-Section: 3 mm x 5 mm

- Load Rating: 100 N

- Medium Load Spring (Blue):

- Outer Diameter: 25 mm

- Free Length: 60 mm

- Wire Cross-Section: 4 mm x 6 mm

- Load Rating: 200 N

- Heavy Load Spring (Red):

- Outer Diameter: 30 mm

- Free Length: 70 mm

- Wire Cross-Section: 5 mm x 8 mm

- Load Rating: 500 N

- Extra Heavy Load Spring (Yellow):

- Outer Diameter: 35 mm

- Free Length: 80 mm

- Wire Cross-Section: 6 mm x 10 mm

- Load Rating: 1000 N

These load ratings are calculated based on the spring’s design and material properties. Actual use may require adjustments according to specific working conditions. Different colors represent different load levels, helping to quickly identify and select the appropriate spring type.

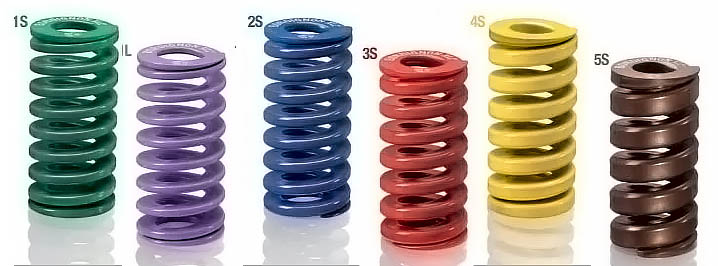

Color Coding

ISO 10243 uses a color coding system to help identify the load capacity of heavy-duty helical compression springs. Each color corresponds to a specific load level. The color coding is as follows:

- Green: Light load

- Suitable for small load applications

- Greater deflection

- Blue: Medium load

- Suitable for medium load applications

- Moderate deflection and load capacity

- Red: Heavy load

- Suitable for larger load applications

- Lesser deflection

- Yellow: Extra heavy load

- Suitable for very large load applications

- Minimum deflection, highest load capacity

This color coding system allows users to quickly identify the load capacity of the springs and select the appropriate type for their application, improving efficiency and reducing the risk of using the wrong load-rated spring.

Color Coding Examples

- Green Springs: Used for light load applications such as small devices or precision instruments.

- Blue Springs: Used for medium load applications such as general industrial machinery.

- Red Springs: Used for heavy load applications such as mold making and heavy machinery.

- Yellow Springs: Used for extra heavy load applications such as large die-casting equipment and high-load industrial equipment.

Specific Color Coding and Load Classification

| Color | Load Level | Typical Applications |

|---|---|---|

| Green | Light Load | Small devices, precision instruments |

| Blue | Medium Load | General industrial machinery |

| Red | Heavy Load | Mold making, heavy machinery |

| Yellow | Extra Heavy Load | Large die-casting equipment, high-load industrial equipment |

These color codes and load levels ensure the correct selection and use of springs in different applications.

ISO 10243 springs, also known as Heavy duty Die Springs, are essential components in various industrial applications. These Compression die springs are engineered to handle significant loads and provide reliable performance. Gold Die Springs are particularly notable for their robustness and are often used in high-stress environments.

As a professional mold spring manufacturer, GUNRI specializes in custom-made springs that comply with various international standards, including ISO 10243.

We are dedicated to providing high-quality products and services tailored to your specific application needs. Contact us to learn more and get a quote .