What is Ball Guided Ejection Bushing?

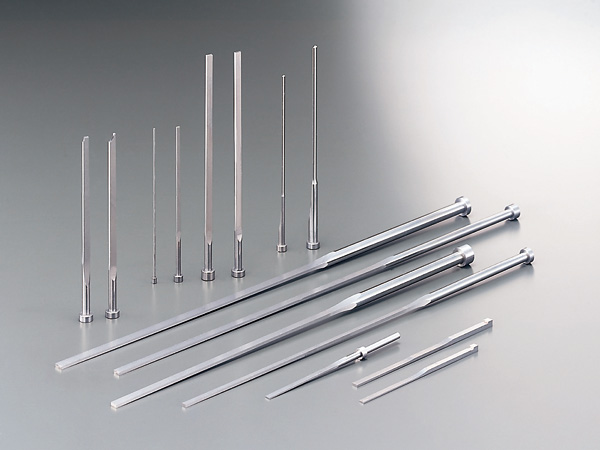

The Ball Guided Ejection Bushing, often simply referred to as a “Ball Bushing,” is a crucial component within the domain of injection molding.

It serves as a precision guiding mechanism designed to facilitate the ejection of molded parts from the mold cavity.

This ingenious device employs a system of precision balls housed within a cylindrical bushing to ensure smooth and accurate ejection of parts. Its primary role is to guide and support the ejection pins, which are responsible for pushing the molded part out of the mold after the injection process is complete.

Table of contents

Working Principles of Ball Guided Ejection Bushing

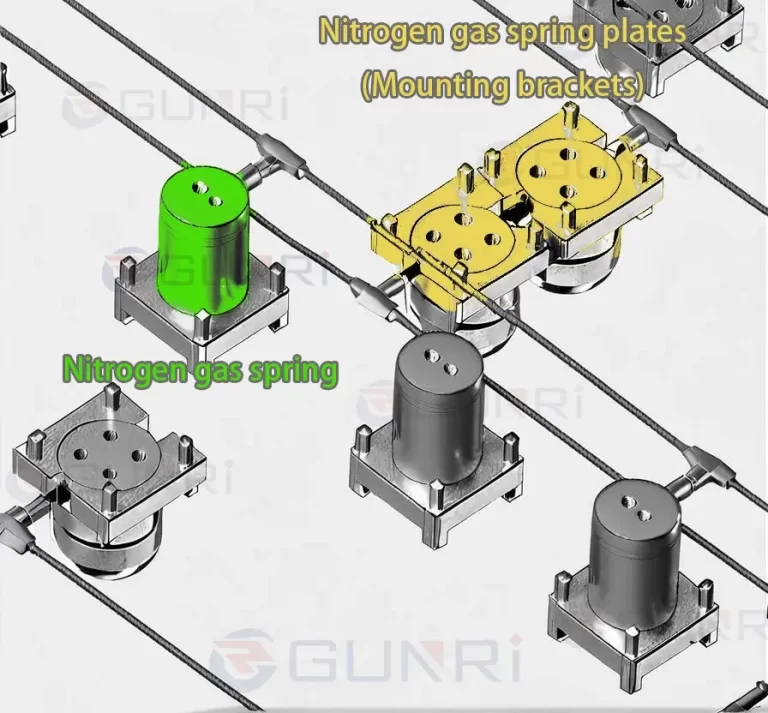

The working principles of the Ball Guided Ejection Bushing are rooted in precision engineering. The cylindrical bushing contains a series of precision steel balls that are strategically positioned to minimize friction and enable the smooth movement of ejection pins.

When the mold opens and ejection is initiated, these steel balls roll along a specific pathway, ensuring that the pins move with the utmost accuracy. The result is a reliable, low-friction system that allows for precise ejection of molded parts.

This mechanism is particularly crucial in preventing damage to both the mold and the parts being produced.

Advantages of Ball Guided Ejection Bushing

The Ball Guided Ejection Bushing offers a range of advantages in the realm of injection molding:

- Precision and Accuracy: This system ensures precise and consistent ejection of molded parts, reducing the likelihood of defects and damage.

- Reduced Friction: The use of steel balls minimizes friction, extending the lifespan of the mold and improving the overall efficiency of the injection molding process.

- Enhanced Durability: The robust design of Ball Guided Ejection Bushings means they can withstand the rigors of high-speed and high-cycle molding operations.

- Cost Savings: By reducing the wear and tear on molds and ensuring consistent part ejection, Ball Guided Ejection Bushings contribute to cost savings in the long run.

Application Areas of Ball Guided Ejection Bushing

Ball Guided Ejection Bushings find application in a wide range of industries and injection molding processes. They are particularly valuable in situations where precision and reliability are paramount, such as:

- Automotive Industry: For the production of intricate and high-precision automotive components.

- Medical Devices: In the manufacture of precise and sterile medical equipment and components.

- Consumer Goods: Used in the creation of consumer products that require intricate molds.

- Electronics: Valuable for molding precise components used in electronic devices.

- Aerospace: In the production of aerospace components that demand extreme precision and reliability.

- Packaging: In the creation of intricate molds for packaging materials and containers.

Get the best price from the Ball Guided Ejection Bushing manufacturer