What is High-speed stamping Tapered Guide Pillar and Bushing

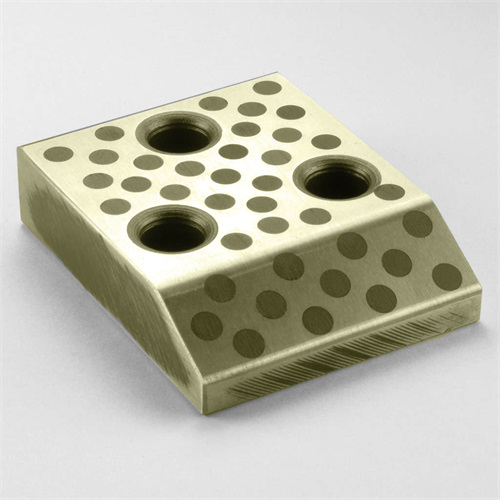

In the realm of motor tooling, Gunri’s Tapered Guide Pillars and Bushings stand out as stalwart components. Their sturdy design, akin to an arm’s robustness, coupled with remarkable hardness, makes them a favored choice in high-speed stamping applications.

The burgeoning new energy sector has brought about a significant uptick in demand for these specialized components. Gunri has been witnessing a remarkable influx of projects associated with the new energy industry, leading to a substantial surge in orders for these high-performing guide pillars and bushings.

What sets these components apart is not only their resilience and durability but also their ability to handle the rigors of high-speed stamping with precision and stability. As a testament to their quality and reliability, Gunri has fostered a loyal customer base, with these sought-after components featuring prominently in their repeat orders. The most prevalent specifications currently revolve around diameters of 80 and 38, reflecting the industry’s reliance on these components for precision and robust tooling solutions.