What is Miniature Ball Bushings

Miniature ball bushings are high-precision mechanical components widely used in systems requiring precise guidance and low-friction movement, such as automation equipment, precision instruments, and machine tools. Their main features include high-quality materials, stability and efficiency, tight fitting, and easy installation.

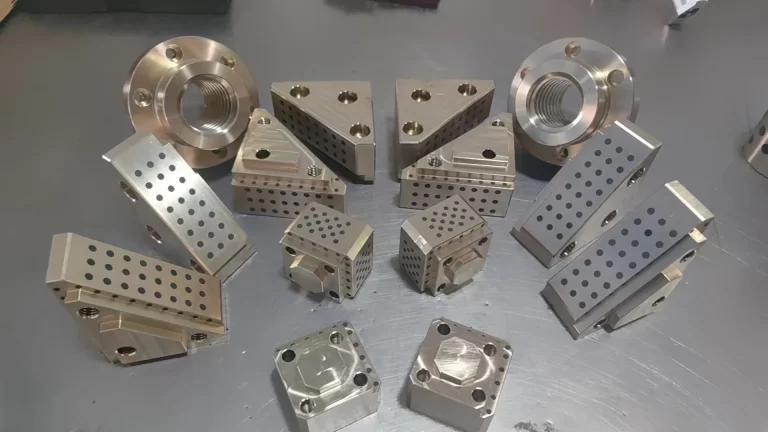

High-Quality Materials

The selection of materials for miniature ball bushings is critical to ensure high performance and durability:

- Copper Ball Bushings: Made from H62 brass, which offers excellent wear resistance and corrosion protection. The high strength and fatigue resistance of brass make these bushings perform exceptionally well even in high-frequency, high-load environments.

- Aluminum Ball Bushings: Made from 6061 aluminum alloy, which is strengthened to enhance corrosion resistance and wear resistance. The superior mechanical properties and good machinability of 6061 aluminum alloy make it widely used in aerospace and precision manufacturing.

Stability and Efficiency

Miniature ball bushings employ advanced manufacturing techniques to ensure stable and efficient operation:

- Advanced Ball Locking Technique: Utilizes a unique ball locking technique to prevent ball seizure or dropout during use. This technique not only improves the durability of the bushings but also ensures smooth operation under heavy loads.

- Rolling Friction: By using rolling friction instead of traditional sliding friction, the friction resistance is greatly reduced. This results in smoother movement and significantly enhances the wear resistance and lifespan of the bushings.

Tight Fitting

The design of miniature ball bushings ensures precise fitting with guide posts, ensuring excellent performance:

- Interference Fit: The bushings and guide posts use an interference rolling fit, which has a very low friction coefficient, ensuring lightweight and flexible movement. This design makes miniature ball bushings particularly effective in applications requiring high-precision guidance.

- Close Fit: Strict manufacturing tolerances and precise machining ensure a close fit between the bushings and guide posts, providing high-precision guidance and reliable operational stability.

Easy Installation and Strong Interchangeability

The design of miniature ball bushings also considers the ease of installation and maintenance:

- Easy Installation: The well-designed structure makes the installation process simple and quick, reducing the time required for equipment setup and maintenance.

- Strong Interchangeability: Standardized manufacturing specifications ensure good interchangeability between different brands and models of ball bushings. This not only reduces spare parts inventory costs but also improves the flexibility and convenience of equipment maintenance.

Summary

Miniature ball bushings, with their high-quality materials, advanced manufacturing techniques, precise fitting, and easy installation features, have become essential components in the mechanical industry. Their excellent performance and durability meet the demands of various high-precision and high-reliability applications.