What is Progressive Stamping Die?

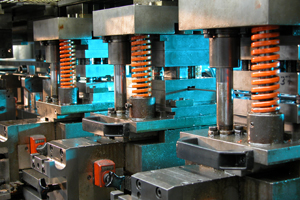

Progressive Stamping Die is a tool used in metalworking designed for consecutively stamping, shaping, and processing metal materials through a series of progressive operations. It’s utilized to produce fully formed metal parts by passing a metal strip or sheet through various workstations in the die, often in conjunction with a mechanical press.

In a Progressive Stamping Die, the metal strip progresses through a sequence of stations, each performing specific operations such as piercing, trimming, forming, coining, and positioning. Each station executes a particular task, ultimately transforming the metal strip into a complete part by the end of the die run. This continuous process enables efficient production of large quantities of metal parts, saving time and cost.

The ‘Pilot Hole’ in a Progressive Stamping Die is crucial; it’s located in the scrap area to precisely position and ensure the accurate location of the part as it progresses through the die. By using pilot holes, the die ensures the part’s precise location throughout the successive operations, maintaining accuracy and quality in the final product.