What materials are suitable for guide pillars and bushings?

Due to the frequent usage and the specialized operational conditions, it is imperative that the materials utilized in the manufacturing of guide pillars and bushings exhibit exceptional toughness and wear resistance.

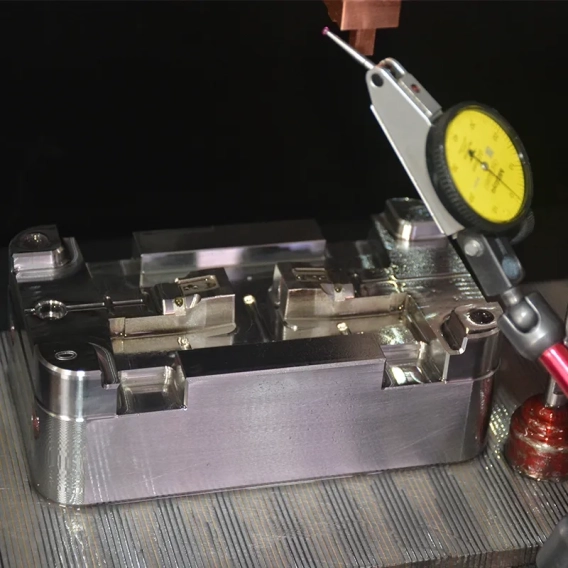

Guide Pillars and Bushings

Commonly employed materials for guide pillars and bushings encompass C45 carbon structural steel, SKD11, SUJ2, and GCr15. Let’s delve into the distinctive characteristics of these materials:

- C45 Carbon Structural Steel: Utilizing C45 carbon structural steel or carbon tool steel is recommended, boasting a heat treatment quenching hardness of approximately HRC45.

- SKD11: For applications with heightened requirements, the preference is given to SKD11 and H13, showcasing a heat treatment quenching hardness of around HRC51.

- SUJ2: Following low-temperature tempering, SUJ2 demonstrates elevated strength, toughness, and wear resistance, significantly prolonging its service life. It finds application in mold components and can also be utilized for manufacturing wire drawing dies, cold heading dies, as well as measuring and toughening tools, bearings, and ball bearings.

- GCr15: GCr15, identified as a high-carbon chromium bearing steel, achieves high hardness and wear resistance after quenching and tempering.

To enhance the durability of guide pillars and bushings by improving toughness and wear resistance, opting for SUJ2 and GCr15 materials is advisable. Nevertheless, the choice of materials may also be contingent on specific application requirements, and it is not obligatory to exclusively use SUJ2 and GCr15 in all instances.