Why Does Surface Roughening Occur on Mold Guide Pins?

The occurrence of surface roughening on mold guide pins is a prevalent issue in the production of metal molds. It has specific implications, mainly manifesting in two key areas:

1. Reduced Production Stability and Efficiency: The phenomenon of surface roughening adversely affects the stability and efficiency of the production process. It leads to an increase in the rejection rate of parts, thereby impacting overall production efficiency.

2. Accelerated Mold Wear: Surface roughening also contributes to more severe mold wear. This, in turn, results in a decreased mold lifespan and a decline in the precision of stamped parts. It necessitates more frequent mold repairs and increases production downtime.

So, what causes the surface of mold guide pins to exhibit this roughening phenomenon? It can be attributed to localized contact or engagement between the guide pins and the mold surface, or it may be due to insufficient hardness of the guide pin surface.

Improvements to mitigate the issue of surface roughening typically involve the following methods:

1. Material Replacement: Opting for guide pin materials with enhanced hardness can help combat surface roughening issues effectively.

2. Surface Treatments: Implementing surface treatments such as hard chrome plating, PVD (Physical Vapor Deposition), or TD (Thermal Diffusion) can significantly enhance the durability and wear resistance of the guide pin surface.

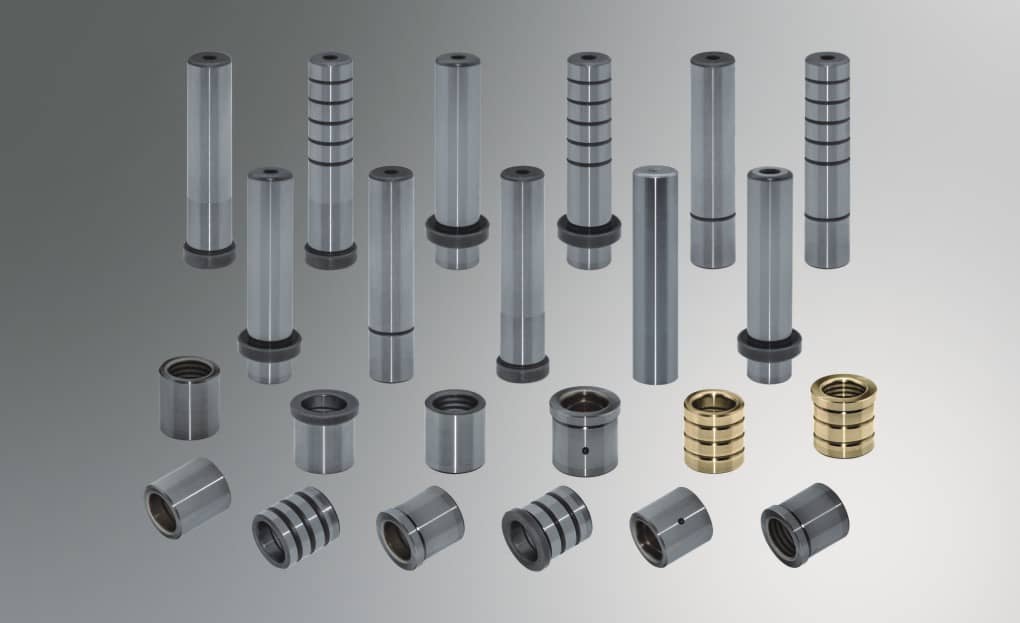

3. Lubrication: Applying lubricating oils or lubricants to the working sections of the guide pin and guide bushing can help reduce friction, thereby minimizing the occurrence of roughening. Additionally, designing multiple oil grooves on the guide pin surface can enhance lubrication and decrease the likelihood of roughening.

When seeking a reliable solution, consider partnering with a reputable mold component manufacturer like Gunri, which specializes in guide pins and guide bushings. Their products are known for their superior quality, ensuring adequate hardness and wear resistance. Moreover, established manufacturers like Gunri often provide dependable delivery services, ensuring timely support for your mold needs.