7 Proven Ways to Reduce Unnecessary Components in Mold Design

Over-engineered molds burden manufacturers with hidden costs: excessive part counts drive up machining, assembly, and maintenance expenses while increasing failure risks. The solution lies in strategic simplification – removing non-essential components without compromising function. Here’s how leading toolmakers achieve leaner designs.

1. Core Principles for Minimalist Design

A. Function-Driven Validation

- Mandatory Check: “Does this component directly enable core mold functions?” (forming, ejection, cooling, venting, alignment).

- Practical Tactic: Replace complex mechanical ejectors with direct hydraulic systems where feasible.

B. Design for Manufacturability (DFM)

- Machining Focus: Avoid geometries requiring 5-axis machining when simpler split inserts suffice.

- Assembly Focus: Design components for single-direction access to streamline fitting.

2. Component Integration Techniques

A. Multifunctional Parts

- Inserts: Embed conformal cooling channels to eliminate separate seals.

- Ejector Pins: Machine venting grooves to remove dedicated vent pins.

- Guide Pillars: Integrate limit shoulders to delete secondary blocks.

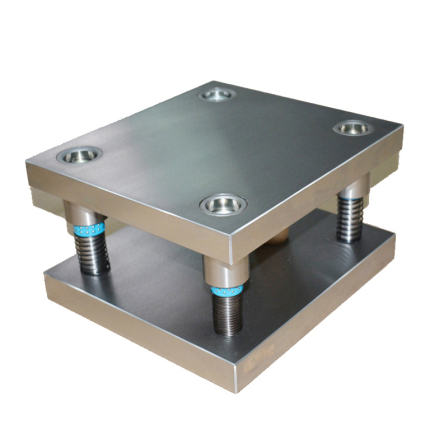

B. Template Optimization

- Machine cavities directly into plates for simple geometries (requires wear-resistance analysis).

- Consolidate cooling channels into template manifolds.

3. Standardization & Modularization

A. Leverage Commercial Standards

- Use catalog components (DME, HASCO, MISUMI) for:

- Mold bases

- Ejector systems

- Fasteners

- Proven Benefits: Faster procurement, guaranteed interchangeability.

B. Modular Design

- Segment molds into functional blocks (e.g., core/cavity, slider units).

- Key Advantage: Enables component reuse across mold families.

4. Simplified Actuation Systems

A. Motion Efficiency

- Prefer direct hydraulic/pneumatic drives over linkage mechanisms.

- Utilize mold opening motion to power sliders via cams or wedges.

B. Ejection Optimization

- Minimize multi-stage systems through strategic pin placement.

- Validate layouts with mold flow analysis.

5. Efficient Cooling Strategies

- Avoid: Unnecessary fittings, sharp bends, and redundant circuits.

- Implement:

- Straight-drilled channels with baffles/bubblers

- Conformal cooling for complex geometries

- CFD-optimized layouts

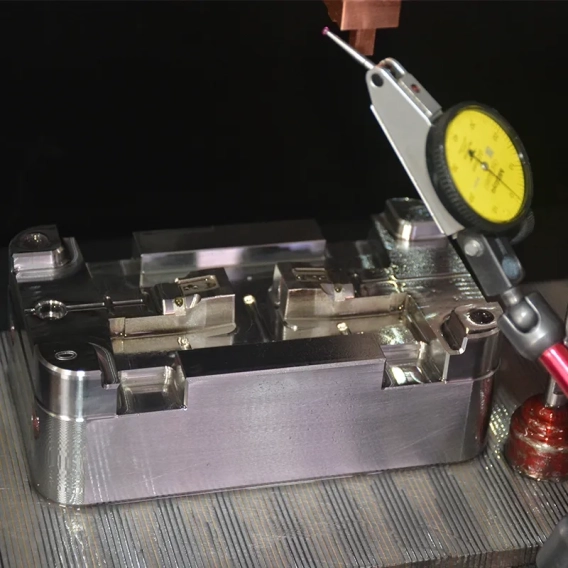

6. Digital Verification

- Essential Tools:

- Mold flow analysis → Optimize gate/ejection locations

- FEA → Validate structural integrity

- Digital assembly checks → Prevent interference issues

7. Collaborative Refinement

- Critical Feedback Loops:

- Toolmakers: “Can this be machined with standard tools?”

- Technicians: “Is sub-15-minute maintenance feasible?”

- Documented Outcome: Cross-functional reviews consistently reduce part counts.