brass ball cage manufacturer

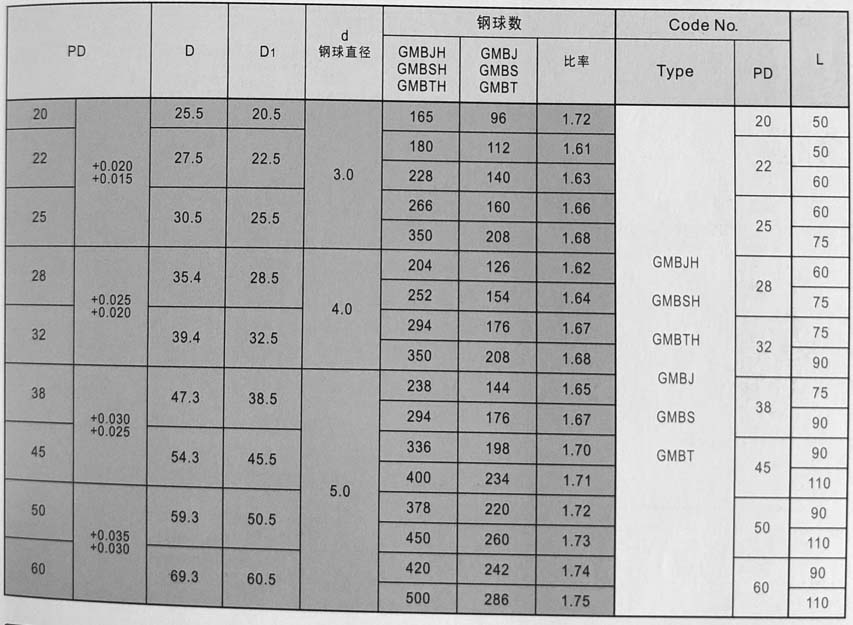

brass ball cage standard size

brass Ball Cage Technical

Brass ball cage price

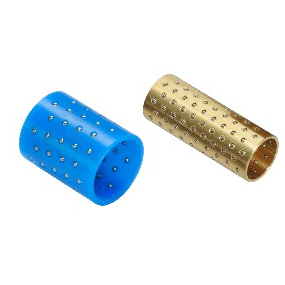

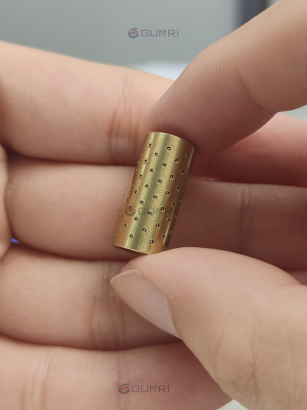

Ball Cage Material

brass die parts ball bearing cage bushing

Common ball distribution patterns:

- Single row: Balls are arranged in a single row, commonly used in smaller guide posts and bushings. This method is simple in structure and low in cost, but has relatively weak load-bearing capacity.

- Double row: Balls are arranged in two rows, increasing the number of balls, improving load-bearing capacity and guiding accuracy.

- Multiple rows: Balls are arranged in multiple rows, further improving load-bearing capacity and guiding accuracy, suitable for large molds and high-precision applications.

- Helical: Balls are arranged in a helical pattern, which can evenly distribute the load, improving guiding accuracy and wear resistance.

- Special distribution: According to specific mold requirements, other special ball distribution patterns can be adopted, such as asymmetric distribution and local dense distribution.”

Explanation of some technical terms:

- Ball distribution pattern: This refers to the arrangement of balls within a ball bushing or retainer.

- Guide post: A cylindrical component that guides the movement of a punch or die in a mold.

- Bushing: A metal lining inserted into a hole to reduce wear and provide a smooth surface for a moving part.

- Load-bearing capacity: The maximum load that a component can withstand without failure.

- Guiding accuracy: The precision with which a component can guide the movement of another component.

Materials and Benefits of Brass in Ball Cages

The use of brass as the primary material for ball cages offers several advantages over other materials like plastic or steel:

Corrosion Resistance: Brass offers superior resistance to corrosion, especially in environments exposed to humidity and chemicals.

Durability: Brass is tough and able to withstand the wear and tear of high-stress environments, ensuring longevity and reducing the need for frequent replacements.

Self-Lubrication: One of the key reasons for choosing brass is its self-lubricating properties, which reduce the need for additional lubrication during operation.

Precision Fit: Brass can be machined to very tight tolerances, ensuring a precise fit that is essential for high-performance molds.

JIS ball cage

DIN ball cage

AISI ball cage

Mini ball cage

misumi-standard BALL CAGE

Ball cages can be categorized based on their application: mold-based and ejection plate-based.

ball cage for mold-based

ball cage for stripper plain/ ejection plate-based

fibro-standard BALL CAGE

In Germany, fibro-standard ball bushings with both needle and ball configurations are well-known, with needle-type bushings being particularly suitable for more precise equipment.

mahr-standard BALL CAGE

In the US, Dayton Lamina and Danly are big names when it comes to high-quality ball bushings.

DANLY-standard ball cage

A distinctive U-shaped ball arrangement characterizes the exterior of DANLY ball cage bushing.

| Part No. | Description | C – Length (in) | D – I.D. (in) | S (in) |

|---|---|---|---|---|

| 6-0806-821 | CAGE 1.00IDX 1.500 OAL-TYPE I | 1.5 | 1 | 0.4375 |

| 6-0808-821 | CAGE 1.00IDX 2.000 OAL-TYPE I | 2 | 1 | 0.6875 |

| 6-0808-822 | CAGE 1.00IDX 2.000 OAL-TYPE II | 2 | 1 | 0.6875 |

| 6-0810-822 | CAGE 1.00IDX 2.500 OAL-TYPE II | 2.5 | 1 | 0.875 |

| … | … | … | … | … |

| 6-1019-822 | CAGE 1.25IDX 4.750 OAL-TYPE II | 4.75 | 1.25 | 1.5 |

| 6-1208-821 | CAGE 1.50IDX 2.000 OAL-TYPE I | 2 | 1.5 | 0.6875 |

| … | … | … | … | … |

| 6-1427-822 | CAGE 1.75IDX 6.750 OAL-TYPE II | 6.75 | 1.75 | 2.8125 |

| 6-1612-821 | CAGE 2.00IDX 3.000 OAL-TYPE I | 3 | 2 | 1.1875 |

| … | … | … | … | … |

| 6-2035-822 | CAGE 2.50IDX 8.750 OAL-TYPE II | 8.75 | 2.5 | 5.125 |

| 6-2416-821 | CAGE 3.00IDX 4.000 OAL-TYPE I | 4 | 3 | 1.3125 |

| … | … | … | … | … |

| 6-2435-822 | CAGE 3.00IDX 8.750 OAL-TYPE II | 8.75 | 3 | 5.125 |

Mini ball cages, due to their compact size and high precision, find applications in sophisticated equipment like chip manufacturing.

For more details, please contact our customer service