Dayton Punch Catalog: Comprehensive Guide for Precision Tooling Solutions

As a leader in the precision tooling industry, Dayton Punch has earned a solid reputation for delivering high-performance punches, dies, and related tooling components. Our Dayton Punch catalog serves as an all-encompassing resource for manufacturers, engineers, and toolmakers who require quality, durability, and consistency in their tooling solutions. This detailed guide will walk you through the broad range of products available in the Dayton Punch catalog, ensuring you find the right solution for your application.

Introduction to Dayton Punch Products

Dayton Punch is renowned for its wide selection of punches, die buttons, retainers, and accessories, all designed to meet the needs of industries such as automotive, aerospace, and electronics. Our products are engineered with precision and are made from high-grade materials that ensure longevity and efficiency. Whether you’re looking for standard tooling or custom solutions, the Dayton Punch catalog offers comprehensive specifications and detailed descriptions of each product, making selection easier and more efficient.

Punches: The Backbone of the Dayton Punch Catalog

At the core of the Dayton Punch catalog are the punches, which are essential tools for metal forming and stamping processes. Dayton offers an extensive array of punches, each designed to fulfill specific application requirements. Let’s explore some of the most prominent types:

Round Punches

Round punches are the most commonly used punch type in various industries. Dayton’s round punches are made from premium high-speed steel and carbide materials, ensuring optimal wear resistance and longevity. Available in different diameters, shank lengths, and point configurations, these punches can be customized to your exact needs.

Shaped Punches

For applications requiring non-round holes, shaped punches such as square, hexagonal, and rectangular punches provide the ideal solution. Dayton’s shaped punches deliver precision cutting with minimized wear, ensuring smooth operation across extensive production cycles. The catalog includes specifications on dimensions and material types, helping users select the perfect fit for their unique tooling requirements.

Specialty Punches

When traditional punches won’t suffice, Dayton’s specialty punches fill the gap. These include extrusion punches, shear punches, and pilot punches, each engineered for unique manufacturing processes. From extruding metal materials to ensuring precise hole alignment, these specialty tools are designed to handle complex operations with ease.

Die Buttons and Retainers: Essential for Efficient Tooling

In addition to punches, Dayton offers a full range of die buttons and retainers, which play a critical role in supporting the punching process. Die buttons ensure that the punch’s cutting edge stays sharp while offering resistance against wear and tear. Dayton’s die buttons are available in a range of shapes, sizes, and material compositions to suit specific manufacturing applications.

Standard Die Buttons

Dayton’s standard die buttons come in a variety of configurations, including plain, shoulder, and ball-lock die buttons. Each type offers unique benefits depending on the type of punch used and the application. The ball-lock system, in particular, facilitates quicker punch and die changes, minimizing downtime and increasing overall productivity.

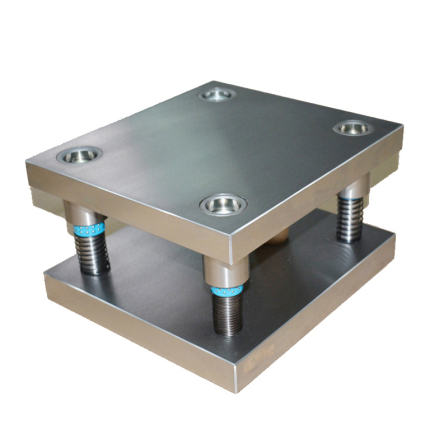

Matrix Retainers

Matrix retainers from Dayton are built to secure the die button firmly in place during the punching process. Made from high-strength steel alloys, these retainers resist the stresses of high-volume production, ensuring tool longevity. In the catalog, users can find detailed technical drawings and compatibility information to help in selecting the proper retainers.

Strippers and Guides: Ensuring Precision and Accuracy

To ensure accurate punch alignment and smooth operation, Dayton’s strippers and guides play a crucial role. These components help maintain the integrity of the punching process by controlling the movement of the punch and workpiece.

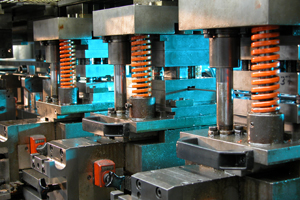

Spring Strippers

Spring strippers are integral in sheet metal forming, ensuring that the punch is retracted smoothly from the material after the punching operation. Dayton’s spring strippers are available in various configurations and force ratings to match specific punch types. High-performance springs used in the strippers guarantee resilience and repeatability in high-speed production environments.

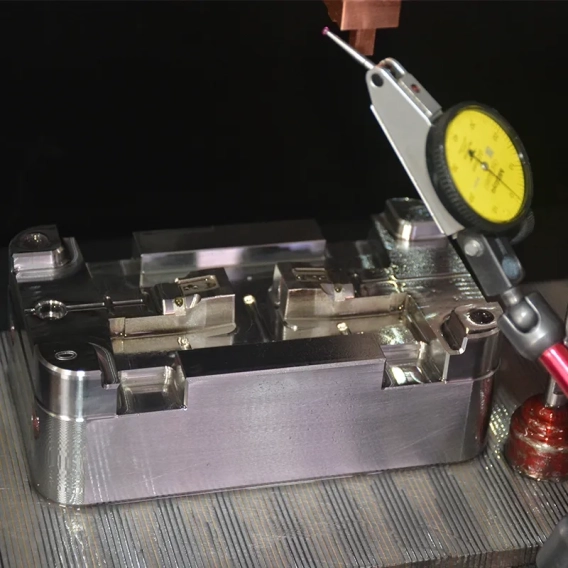

Guide Pins and Bushings

Guide pins and bushings are essential components for maintaining alignment between the punch and die. Dayton’s catalog offers a wide selection of guide pins and bushings in both standard and custom sizes. Hardened steel guide pins provide superior wear resistance, while bushings ensure smooth operation and minimal friction.