DIN 6325 vs DIN 7979: Dowel Pins Comparison

What Are DIN 6325 and DIN 7979 Dowel Pins?

DIN 6325 and DIN 7979 are two commonly used dowel pin standards defined by the German DIN system. They are widely used in molds, jigs, automation equipment, and other precision mechanical assemblies. While both look similar, their structure and applications differ significantly.

Key Differences Between DIN 6325 and DIN 7979

| Feature | DIN 6325 | DIN 7979 |

|---|---|---|

| Structure | Solid body | Hollow with internal thread |

| Thread | None | Yes (internal) |

| Removal | Not designed for removal | Easy removal using a bolt |

| Cost | Lower | Slightly higher |

| Common Use | Permanent alignment | Serviceable and reusable positioning |

| Tolerance | h6 | h6 |

How to Choose the Right Dowel Pin?

Use DIN 6325 if you need:

- Permanent alignment for mold bases or die sets

- A cost-effective solution

- Low maintenance

Use DIN 7979 if you need:

- Easy disassembly and maintenance

- Quick-change tooling in CNC or jigs

- Hot runner mold system alignment

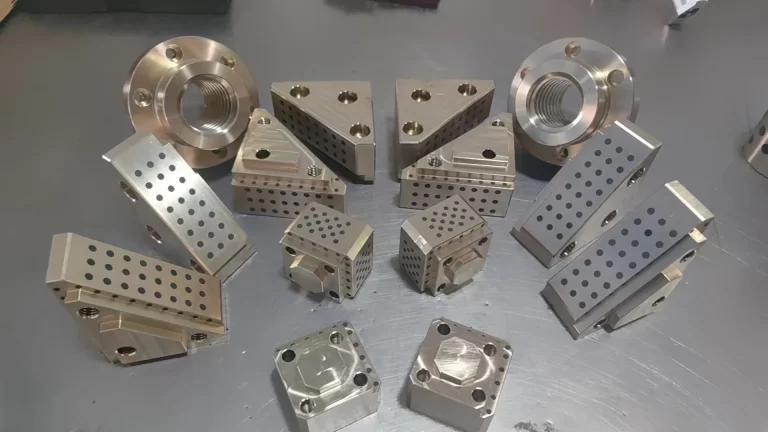

Common Applications

| Application | DIN 6325 | DIN 7979 |

|---|---|---|

| Injection molds | ✔️ Core to base alignment | ✔️ Hot runner components |

| Stamping dies | ✔️ Base alignment | ✔️ Detachable fixtures |

| CNC tooling | ✔️ Fixed workholding | ✔️ Modular setups |

| Automation assembly | ❌ | ✔️ Quick-change fixtures |

| Inspection jigs | ❌ | ✔️ Removable locating pins |

Installation Tips

- Recommended hole tolerance: H7

- Dowel pin tolerance: h6

- For DIN 7979, use proper extraction bolts for removal

- Use light press-fit tools to ensure proper alignment

Contact Us for Quotes or Free Samples

We supply a full range of precision dowel pins, including:

- DIN 6325 – Solid Dowel Pins

- DIN 7979 – Tapped Dowel Pins

- MSTM / MSTH / MS Series – Threaded mold-use pins

Contact us today for technical datasheets, samples, or custom manufacturing support.

Email: milla@gunri.com.cn