Enhancing Mold Cooling for Optimal Part Quality

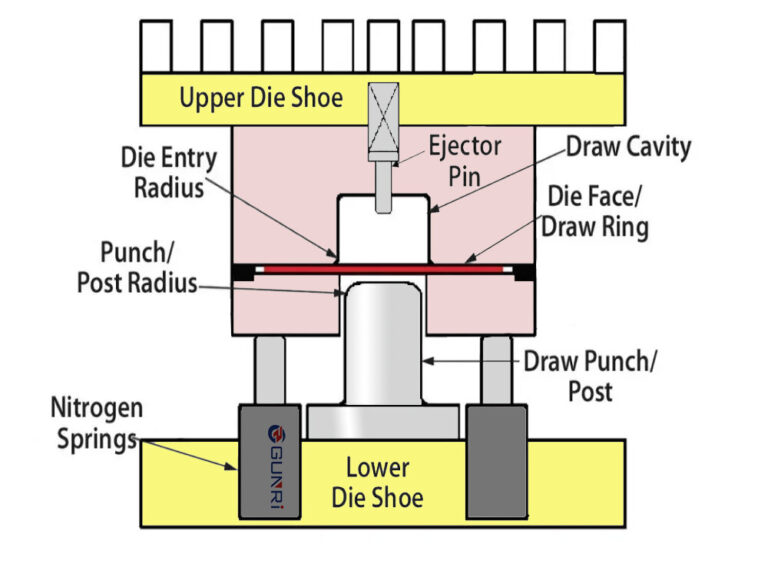

In the intricate realm of manufacturing, achieving uniform cooling in molds, especially within hard-to-cool areas, is a critical aspect that directly impacts part quality. While uniform cooling might not necessarily drastically reduce cycle times, its significance lies in preventing non-uniform part cooling, a factor that often leads to part warpage and subsequent rejections. Let’s delve into the importance of uniform cooling, and how the choice of mold materials plays a crucial role in this endeavor.

A Shield Against Part Warpage

Uniform cooling is a guiding principle that seeks to maintain consistent temperature distribution throughout the mold, ensuring that each part cools at the same rate. This is particularly vital in areas that are challenging to cool, as non-uniform cooling can result in uneven shrinkage and distortion. These deviations from the intended shape can render parts defective, leading to increased waste and reduced overall efficiency.

Table of Mold Material Thermal Conductivity

| Material | Hardness | Hardness Scale | Thermal Conductivity (Btu/ft-hr°F) |

|---|---|---|---|

| Copper Alloy | 190 BHN | BHN | 140 |

| Aluminum | 165 BHN | BHN | 95 |

| Copper Alloy | 28 HRC | HRC | 75 |

| Copper Alloy | 38 HRC | HRC | 60 |

| 4130 | 215 BHN | BHN | 22 |

| P-20 | 30 HRC | HRC | 19 |

| 0-1 | 60 HRC | HRC | 16 |

| S-7 | 52 HRC | HRC | 16 |

| H-13 | 50 HRC | HRC | 15 |

| M-2 | 62 HRC | HRC | 14 |

| 440 Stainless | 54 HRC | HRC | 14 |

| 420 Stainless | 50 HRC | HRC | 11 |

Selecting Mold Materials: The Thermal Conductivity Factor

When it comes to ensuring uniform cooling, the choice of mold materials is a key determinant. Table 2 provides approximate thermal conductivity values for various mold materials. It’s important to note that these values can vary significantly based on factors such as the manufacturer, heat treatment, and operating temperature. Copper alloys and aluminum, known for their high thermal conductivity, excel in promoting uniform cooling. They efficiently transfer heat away from the part, helping to maintain consistent cooling rates.

The Road to Quality and Efficiency

In the quest for superior part quality and manufacturing efficiency, achieving uniform cooling takes center stage. Preventing part warpage by maintaining consistent cooling rates significantly reduces reject rates and enhances overall productivity. By carefully selecting mold materials with appropriate thermal conductivity properties, manufacturers can pave the way for a smoother production process and impeccable end-products. The right material choice becomes a critical step towards mastering the delicate art of mold cooling, ultimately setting the stage for manufacturing success.

Unlock the Power of Optimal Mold Cooling

At Gunri, we understand the intricate dynamics of mold cooling and its impact on quality. Our advanced mold components are designed to enhance uniform cooling, ensuring that your production processes run smoothly and your parts are of the highest quality. Contact us today to explore how our precision mold solutions can revolutionize your manufacturing journey.