Guide Pillar and Guide Bush Manufacturer in China for Precision

Precision engineering is the backbone of modern mold manufacturing, stamping dies, and a wide array of industrial tooling systems. At the center of these mechanisms lie guide pillars and guide bushes—components that dictate stability, alignment, and long-term operational reliability. In China, manufacturers specializing in these parts are rapidly advancing their capabilities, offering solutions that meet global expectations for accuracy, durability, and cost efficiency.

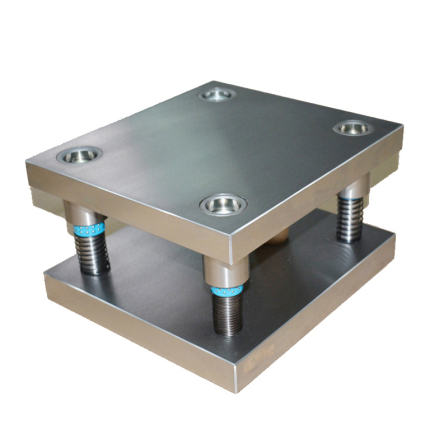

The Role of Guide Pillars and Guide Bushes in Industrial Tooling

Guide pillars and guide bushes serve as the essential alignment system within molds and dies. They ensure that moving plates glide seamlessly, maintain consistent tolerances, and minimize wear during high-frequency operations. These components must withstand repetitive impact, frictional forces, and thermal variations without losing dimensional integrity. As manufacturing sectors demand higher speeds and ultra-tight tolerances, the engineering sophistication of these guide systems becomes even more critical.

High-quality manufacturers apply meticulous machining techniques, precision grinding, and robust quality control protocols to ensure each pillar–bush pair functions as a unified, perfectly matched set. This symbiosis is fundamental to the lifespan and stability of any tooling mechanism.

Why China Has Become a Global Source for Precision Components

China’s industrial ecosystem has undergone a profound transformation. Beyond large-scale production capabilities, the country now houses clusters of specialized factories equipped with CNC centers, cylindrical grinders, automated polishing lines, and advanced surface-treatment technologies. These facilities combine mass-production efficiency with fine craftsmanship, resulting in guide components that meet the expectations of global mold makers.

Moreover, Chinese manufacturers have embraced international standards such as ISO, DIN, and JIS, ensuring compatibility with global tooling systems. Through continual investment in metallurgy, heat-treatment processes, and inspection equipment, they have positioned themselves not only as suppliers but as engineering partners to manufacturers worldwide.

Materials and Treatments That Define High-Precision Performance

A guide pillar and guide bush system is only as reliable as the materials and treatments used to create it. Leading Chinese manufacturers utilize hardened tool steels, alloy steels, and performance-enhancing materials such as bronze with embedded solid lubricants. These materials are selected for their tensile strength, wear resistance, and ability to retain dimensional accuracy under extreme operational conditions.

Heat-treatment processes—vacuum hardening, nitriding, carburizing, and quenching—further enhance surface hardness and internal stability. Some factories also offer specialized coatings including titanium nitride (TiN), DLC, and MG2 coatings for reduced friction and extended lifespan. These metallurgical refinements ensure the entire guide system operates with minimal vibration, consistent alignment, and prolonged durability.

Precision Manufacturing and Quality Control Standards

The production of guide pillars and guide bushes demands meticulous attention to detail. Every component passes through a sequence of machining stages: rough turning, centerless grinding, precision grinding, honing, and final finishing. Incremental measurements taken during each step ensure strict adherence to specified tolerances.

Dimensional inspections using coordinate measuring machines (CMM), concentricity tests, hardness verification, and surface-roughness evaluations guarantee that the completed products meet exacting standards. This disciplined approach results in components that align flawlessly, reduce friction, and perform consistently even in high-speed or heavy-duty applications.

Choosing the Right Manufacturer for Your Requirements

Selecting a suitable manufacturer involves evaluating more than just catalog specifications. Companies should assess the supplier’s engineering support, customization capabilities, material certifications, and consistency in meeting delivery timelines. A reliable manufacturer maintains transparent communicatio