High-Precision Needle Roller Guide Posts: A Revolution in Linear Motion Technology

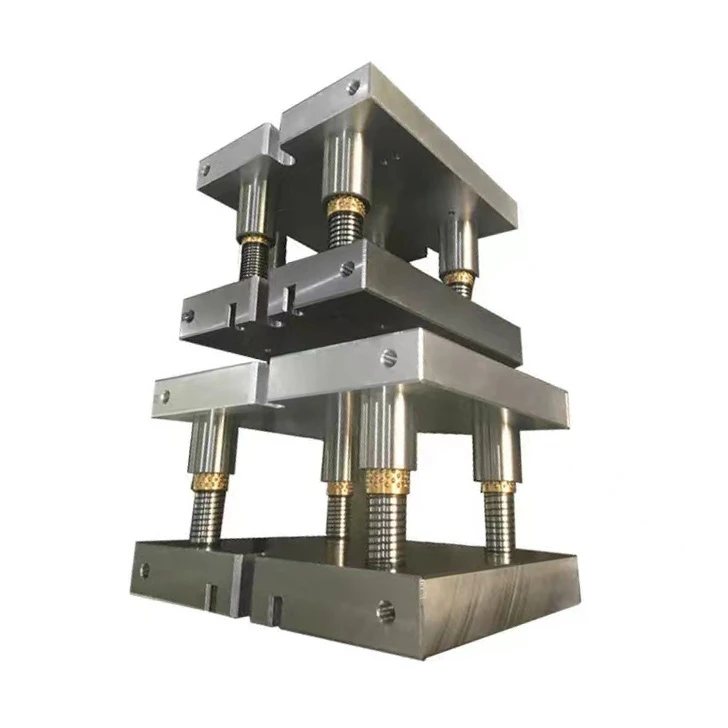

High-precision needle roller guide posts are advanced mechanical components that offer significant improvements over traditional guide posts. Their unique design, which incorporates needle rollers, reduces collisions, friction, and vibrations during operation, enabling ultra-high precision linear motion. This makes them particularly suitable for precision machining, automated equipment, and high-end manufacturing industries.

Compared to traditional ball guide posts, high-precision needle roller guide posts have several distinct advantages. The needle roller design allows for more even pressure distribution, which enhances both the stability and precision of the guide posts. This design also significantly extends their service life, as needle roller guide posts are more resistant to wear and deformation that commonly affect ball guide posts after extended use. This resistance ensures they maintain high efficiency over long periods.

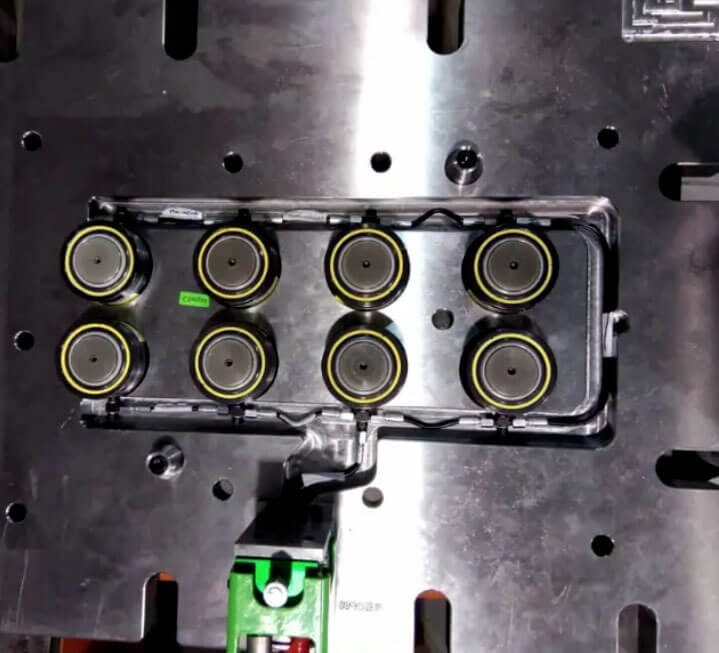

Furthermore, the design of high-precision needle roller guide posts considers adaptability to various complex operating conditions. They perform excellently under high loads, high speeds, and high-temperature environments, ensuring the stable operation of equipment. This makes them essential in applications that demand high precision and reliability.

In summary, high-precision needle roller guide posts excel in shock absorption, friction reduction, and pressure distribution, which contributes to their prolonged service life and stable performance. These attributes make them the ideal choice for linear motion guide posts in the industry. Their widespread application not only enhances precision machining and automated equipment but also provides robust technical support for high-end manufacturing.