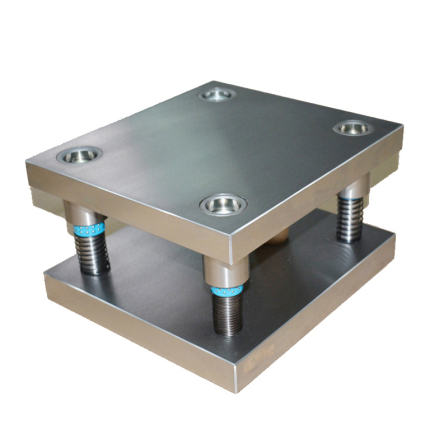

High-Precision Needle Roller Guide Posts: The Perfect Form of Linear Motion Guide Posts

High-precision needle roller guide posts are mechanical components that significantly differ from traditional guide posts. Their design incorporates needle rollers, an innovation that effectively reduces collision, friction, and vibration during use, achieving ultra-high precision linear motion. This feature makes high-precision needle roller guide posts widely applicable in precision machining, automated equipment, and high-end manufacturing industries.

Compared to traditional ball guide posts, the high-precision needle roller guide posts offer a distinct advantage through their unique needle roller design. The needle rollers can distribute pressure more evenly, which not only enhances the stability and precision of the guide posts but also significantly extends their service life. Traditional ball guide posts tend to wear out and deform after prolonged use, whereas needle roller guide posts are better equipped to resist these issues, maintaining high efficiency over an extended period.

Moreover, the design of high-precision needle roller guide posts takes into account adaptability to various complex operating conditions. For instance, they maintain excellent performance under high load, high speed, and high-temperature environments, ensuring the stable operation of equipment. This makes them indispensable in applications requiring high precision and reliability.

Applications and Benefits

The high-precision needle roller guide posts are utilized in a wide range of applications due to their robust performance characteristics. They are essential in industries where precise linear motion is critical, such as:

- Precision Machining: In CNC machines and other precision tools, the accurate linear movement facilitated by needle roller guide posts ensures high-quality production with minimal errors.

- Automated Equipment: In automated production lines, their reliability and durability reduce maintenance costs and downtime, enhancing overall productivity.

- Medical Devices: The precise and smooth movement provided by needle roller guide posts is crucial in medical equipment, where accuracy can directly impact patient outcomes.

- Robotics: In robotics, especially in precision-driven tasks, these guide posts ensure consistent and precise motion, contributing to the reliability of robotic systems.

Technical Specifications and Customization

High-precision needle roller guide posts come in various sizes and configurations to meet the specific needs of different applications. Key specifications often include:

- Load Capacity: They are designed to handle high loads without compromising performance.

- Speed: Capable of maintaining precise motion at high speeds.

- Temperature Range: Operable in a wide range of temperatures, making them suitable for diverse industrial environments.

- Material: Typically made from high-quality steel or alloy to ensure durability and resistance to wear and tear.

Customization options are available to cater to unique application requirements. This includes modifications in dimensions, materials, and additional coatings for enhanced performance in specific conditions.

Future Trends and Innovations

The development of high-precision needle roller guide posts continues to evolve with advancements in technology and engineering. Future trends include:

- Smart Guide Posts: Integration with sensors and IoT technology for real-time monitoring and predictive maintenance, reducing the likelihood of unexpected failures.

- Advanced Materials: Use of new materials such as ceramics or composite materials to further improve durability and performance under extreme conditions.

- Eco-friendly Designs: Innovations aimed at reducing the environmental impact of manufacturing and operation, including the use of recyclable materials and more efficient production processes.

Conclusion

In summary, high-precision needle roller guide posts, with their exceptional capabilities in shock absorption, friction reduction, and pressure distribution, demonstrate a prolonged service life and stable performance. They represent the perfect form of linear motion guide posts in the industry. Their widespread application not only advances precision machining and automated equipment but also provides robust technical support for high-end manufacturing. As technology continues to advance, these guide posts are poised to play an even more critical role in the future of industrial automation and precision engineering.