How to Choose Punch and Die Materials for Automotive Motor Lamination Stamping

In the fast-growing new energy vehicle (NEV) industry, the automotive motor is one of the most critical components. At the heart of the motor lies the silicon steel lamination stack, which must be produced with precision stamping dies capable of maintaining accuracy over millions of strokes.

For toolmakers and stamping plants, the selection of punches and dies directly determines production efficiency, product quality, and overall tooling cost. This article provides a practical guide on how to choose the right punch and die materials for silicon steel lamination stamping, and highlights the related mold components widely used in this industry.

Why Material Selection Matters

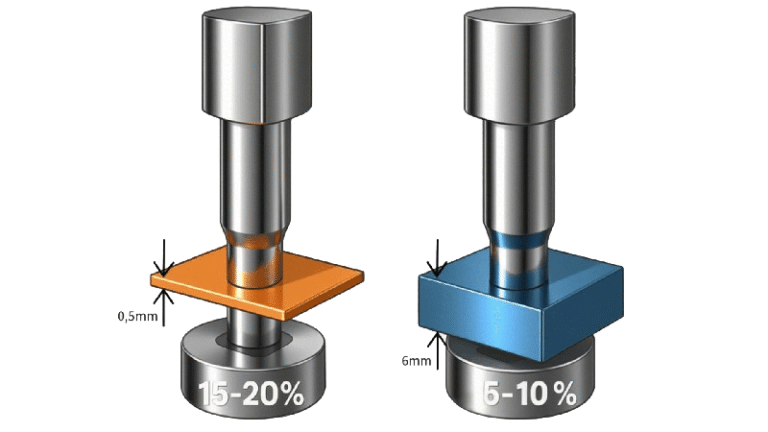

- High Wear Resistance – Silicon steel sheets are abrasive and can quickly dull cutting edges.

- Anti-Galling Performance – Adhesion of material to punch flanks is a common failure mode.

- Dimensional Stability – Precision is crucial; even small burrs or distortions affect motor performance.

- Tooling Cost per Part – Long tool life reduces downtime and lowers the cost per stamped piece.

Common Materials for Punches and Dies

1. Cold-Work Tool Steels

- D2 (SKD11 / 1.2379)

- Widely used, good wear resistance.

- Limitations: relatively brittle, may chip in high-speed production.

2. Powder Metallurgy High-Speed Steels

- PM-M4 / CPM-M4

- Very fine carbide distribution.

- Superior wear resistance + higher toughness compared with D2.

- Suitable for medium to high-volume stamping of silicon steel laminations.

3. Tungsten Carbide

- Exceptional wear resistance, ideal for very high production runs.

- Often applied as carbide inserts brazed to a steel body to reduce cost and avoid fracture risk.

- Higher initial cost but lower cost per part in long production.

Surface Treatments to Extend Tool Life

- PVD Coatings (TiN, TiCN, AlCrN, DLC): Reduce friction and galling, improve surface hardness.

- Nitriding / Surface Hardening: Improve wear and fatigue resistance of dies.

- Polished Cutting Edges: Minimize burrs and prevent early adhesion.

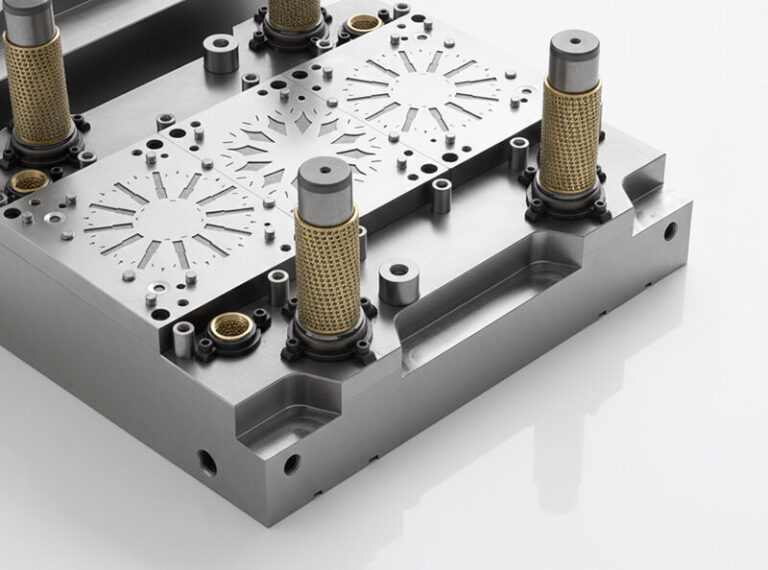

Other Critical Mold Components in EV Motor Stamping

Beyond punches and dies, several precision mold components are essential in silicon steel stamping dies:

- Dowel Pins & Locating Pins – Ensure accurate alignment of die sets.

- Guide Posts & Bushings – Maintain precise movement of upper and lower die shoes.

- Nitrogen Gas Springs – Provide stable and long-lasting force for stripper plates.

- Wear Plates & Inserts – Protect high-stress areas and allow easy replacement.

- Vent Dowel Pins – Help with air evacuation and scrap removal at high speeds.

Practical Tips for Selection

- Match material to production volume:

- Low to medium volume → D2 or improved cold-work steels.

- Medium to high volume → PM-M4.

- Ultra-high volume → Tungsten carbide inserts.

- Always combine material with coating: A well-applied PVD coating can double or triple tool life.

- Design for replaceable inserts: Minimizes downtime and reduces cost of replacement.

- Work with experienced component suppliers: Reliable partners can advise on the right balance between wear resistance, toughness, and cost.

Conclusion

As the electric vehicle and new energy industry continues to grow, demand for high-precision stamping tools and mold components will only increase. Choosing the right punch and die materials, combined with advanced coatings and reliable standard components, is the key to achieving longer tool life, higher efficiency, and better quality.

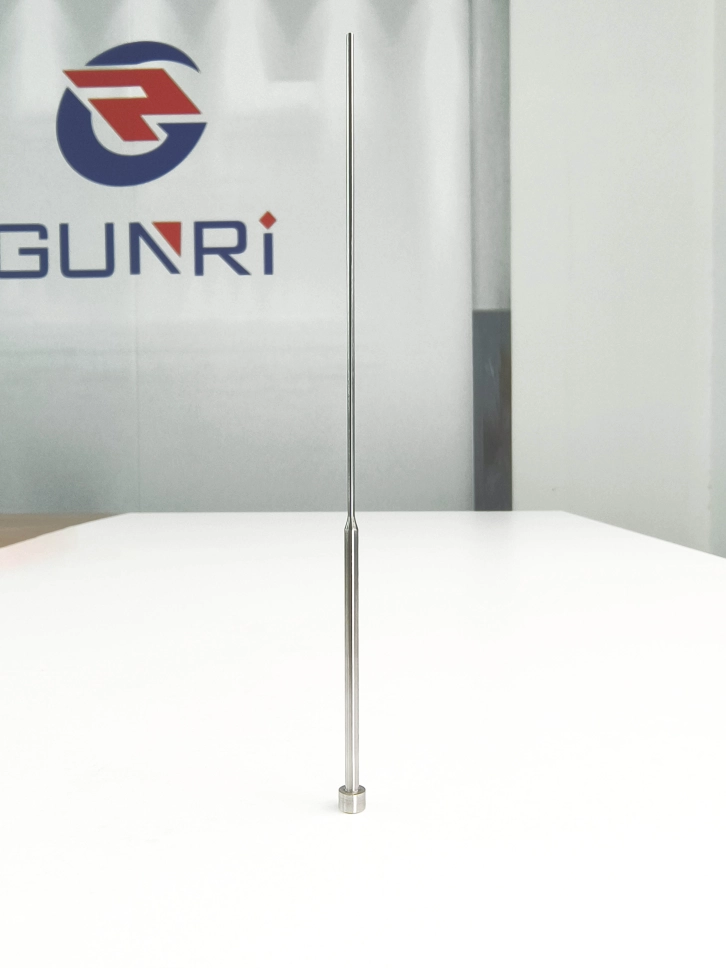

If you are looking for a trusted supplier of precision mold components—including punches, dies, dowel pins, nitrogen gas springs, and custom inserts—our team at GUNRI is ready to support your projects.

Contact us today to discuss your requirements and get expert recommendations for your stamping tools.