Maintenance Guidelines for Mold Components – Ejector Sleeve and Pin

Maintenance Guidelines for Mold Components – Ejector Sleeve and Pin

To ensure effective maintenance of mold components, specifically the ejector sleeve and pin, the following steps should be taken into consideration:

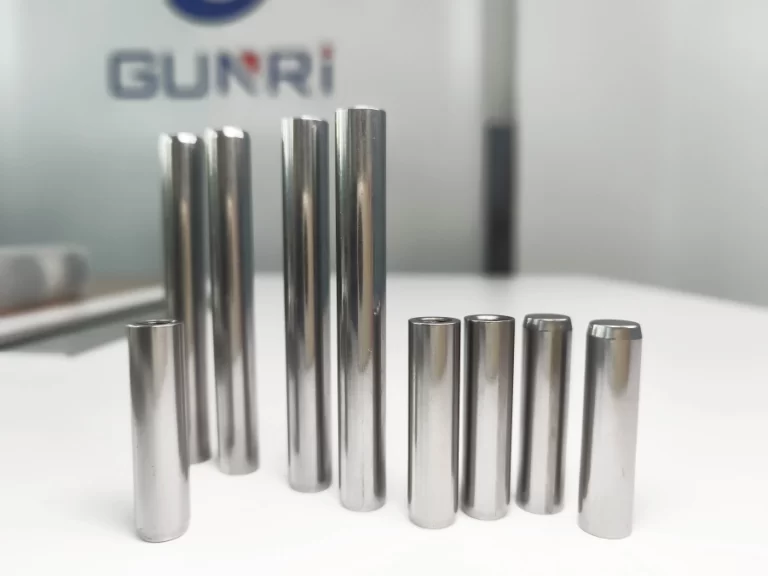

- Rust Prevention and Lubrication:

It is crucial to apply rust prevention and lubrication to the ejector sleeve and pin. Although manufacturers typically apply rust inhibitors during production, extended periods of inactivity may lead to rust formation. Rust can compromise the functionality of the ejector sleeve and pin, reducing efficiency and potentially damaging machinery. Therefore, rust prevention and lubrication are critical steps in maintaining these components.

- Demagnetization Maintenance:

Effective demagnetization maintenance is essential for ejector sleeves and pins. Over time, these components may accumulate magnetic properties during usage. Demagnetization is necessary to prevent material blockages caused by magnetic attraction.

- Polishing:

Polishing the ejector sleeve and pin is a significant aspect of maintenance. This process aims to reduce wear and tear on the components, thereby prolonging their lifespan.

- Inspection and Maintenance Monitoring:

Regular inspection and monitoring of the maintenance status of ejector sleeves and pins are necessary. Proper storage practices should be observed to prevent loss or damage to components.

By adhering to these maintenance guidelines, the longevity and performance of mold components, specifically ejector sleeves and pins, can be preserved effectively.