High-Precision Needle Roller Guide Posts: The Perfect Form of Linear Motion Guide Posts

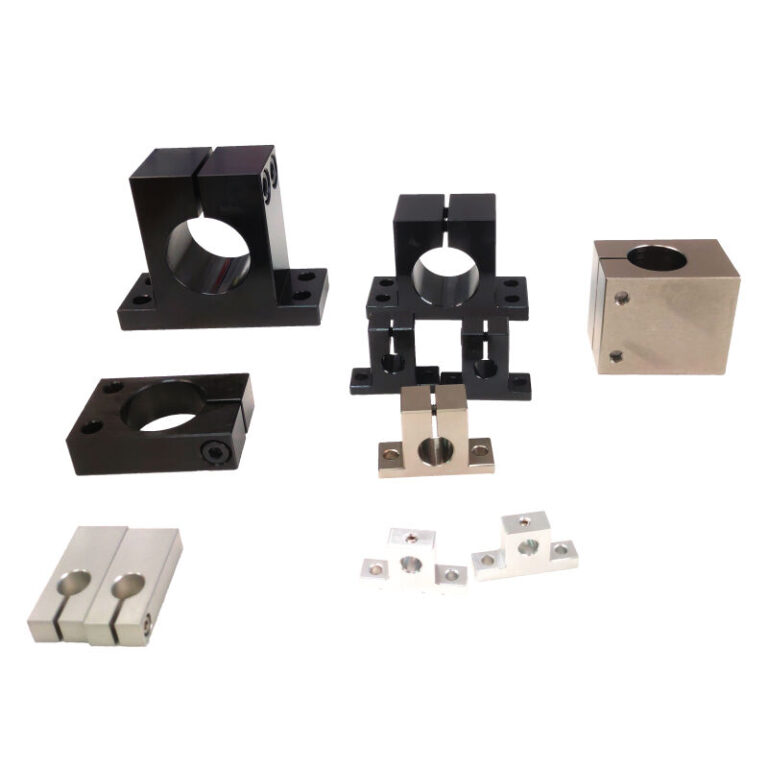

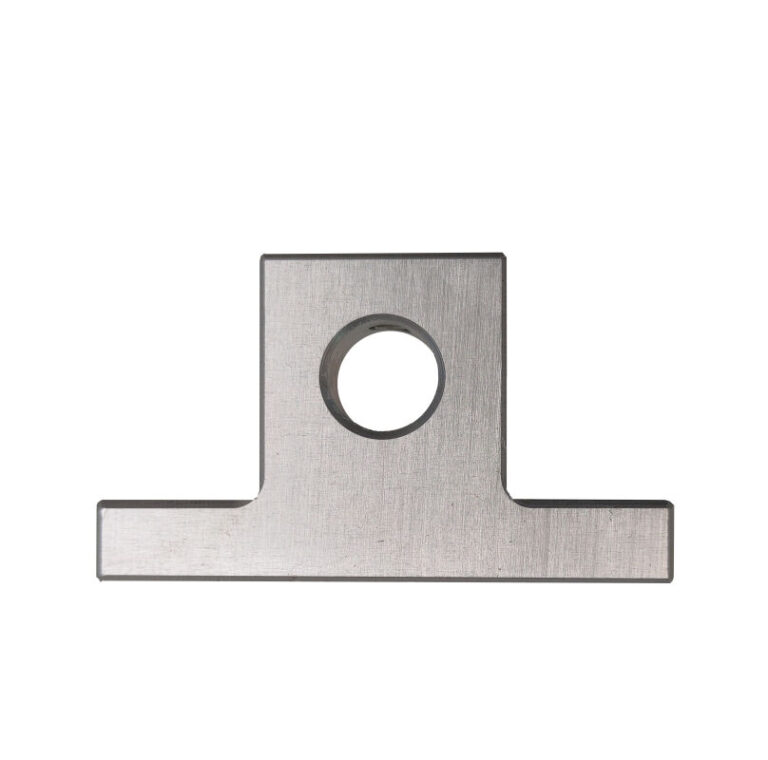

High-precision needle roller guide posts are mechanical components that significantly differ from traditional guide posts. Their design incorporates needle rollers, an innovation that effectively reduces collision, friction, and vibration during use, achieving ultra-high precision linear motion. This feature makes high-precision…