Your Profesional Stamping Die Components manufacturer

Stamping Die Components —is what we do best

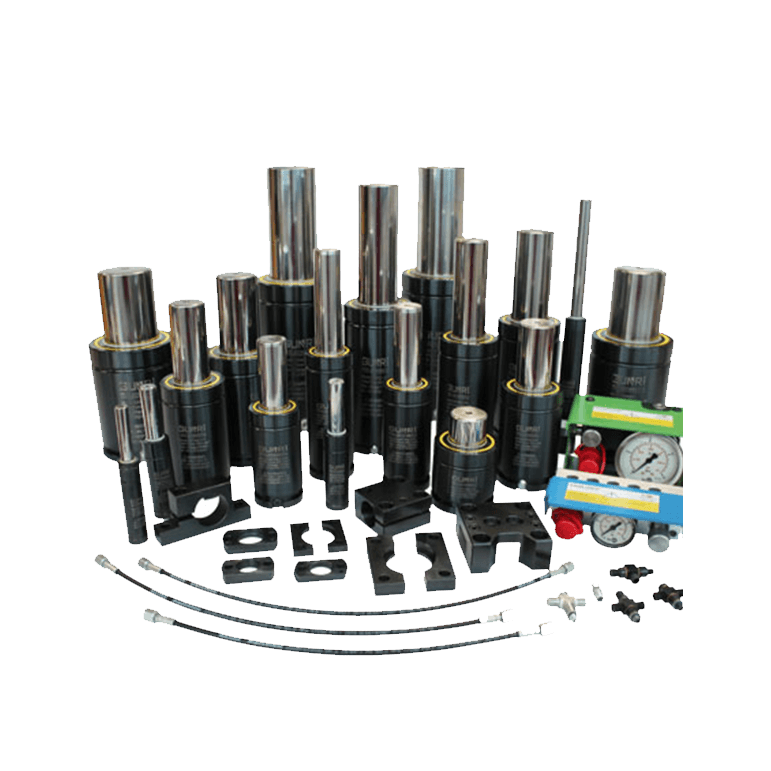

We manufacture a variety of Stamping Die Components tailored to your project requirements. We offer customization based on various standards and dimensions to meet your specific needs.

Whether you’re looking to cut expenses in your production line or seeking customized solutions for your specific needs, Gunri is your go-to partner for