Unleashing the Superior Performance and Application Advantages of Million Guide

An Overview of the Core Highlights of Million Guide

Million Guide has become a standout in industrial components, boasting remarkable advantages in accuracy, rigidity, and product lifespan. These features not only set it apart but also underscore its irreplaceable value within industrial production processes.

A Paragon of High-Precision Guidance

Million Guide shines when it comes to guiding straightness. It is especially suitable for die molds with minuscule clearances, such as those used in thin foil punching operations. In these highly precise manufacturing scenarios, even the slightest deviation can ruin the final product. However, Million Guide’s precision-guiding capabilities ensure that every stroke is on point, guaranteeing the highest level of machining accuracy.

Outstanding Rigidity for High-Quality Output

The rigidity of Million Guide plays a crucial role in manufacturing top-notch products. By maintaining an even punch-die clearance, it effectively prevents punching inclinations. This consistency is key because any tilting during the punching process can lead to uneven edges and unwanted burrs. With Million Guide, manufacturers can count on producing items with smooth, clean edges, meeting the strictest quality standards.

The Secret to Prolonging Product Life

One of the most notable features of Million Guide is its ability to extend the life of punching tools. The smooth strokes enabled by its rollers minimize the chipping of punch-dies. As a result, the frequency of maintenance is significantly reduced, which in turn cuts down on production downtime and overall costs. This long-term durability makes Million Guide a cost-effective choice for industries that rely on continuous, high-volume production.

Premium Materials Laying a Solid Foundation

Needle Roller Cage

The needle roller cage of Million Guide is made of plastic. This material choice brings multiple benefits. Plastic is lightweight, which reduces the overall weight of the unit without sacrificing strength. Additionally, it offers excellent wear resistance, ensuring a long service life even under continuous use.

Needle Rollers

Crafted from hardened steel, the needle rollers are the workhorses of Million Guide. Their high strength allows them to withstand heavy loads and repeated stress. This durability is essential for maintaining the integrity of the guiding function over extended periods, contributing to the overall reliability of the system.

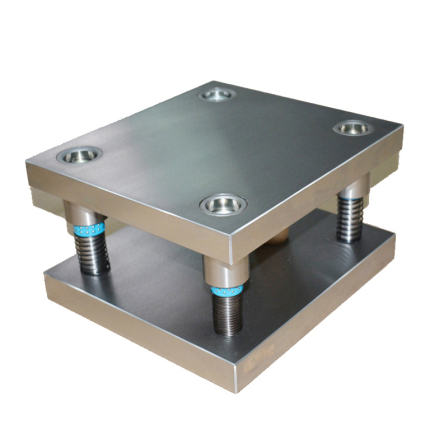

Guide Bush and Guide Pillar

Both the guide bush and guide pillar are fabricated from a hardened tool steel alloy, with a hardness rating of 60 ± 2 HRC. This high hardness endows them with exceptional wear resistance and stability, locking in the guiding precision, regardless of the intensity of use.

Diverse Execution Options to Meet Varied Needs

Ø 16 Specification

The Ø 16 specification of Million Guide comes with 4 running surfaces. This design makes it an ideal choice for specific working conditions. For instance, in small-scale molds or equipment where space is at a premium, the Ø 16 unit can provide reliable guidance without taking up excessive room.

Ø 12 – Ø 60 Specification

Spanning from Ø 12 to Ø 60, these sizes feature 6 running surfaces. They find widespread application in medium-sized molds. The additional running surfaces offer enhanced stability, making them the go-to option for a broad range of manufacturing tasks that require a balance between size and precision.

Ø 80 Specification

The Ø 80 specification of Million Guide is equipped with 8 running surfaces. This configuration is tailored for large molds or applications where the highest level of guiding accuracy is non-negotiable. The increased number of running surfaces distributes the load more evenly, delivering unrivaled precision.

Flexible Application Scenarios Opening Up Endless Possibilities

Million Guide has permeated various industrial fields. In the automotive manufacturing sector, it ensures the precision of parts assembly, from engine components to body panels. In the production of electronic devices, it enables the accurate stamping of tiny, intricate parts. Even in the realm of precision instrument processing, Million Guide’s reliability and accuracy make it an indispensable tool, demonstrating its versatility and wide-ranging significance.