What Mold Components to Import from China for Profitable Business?

Sourcing high-quality mold components from China has become a profitable strategy for many global mold makers, machine builders, and tool distributors. However, to ensure long-term success, it’s essential to choose the right components and avoid common pitfalls.

As a mold accessory manufacturer and exporter based in China, we’ve supported clients from over 30 countries in selecting the most cost-effective and high-demand components for their markets. Here’s our perspective on what to import — and what to watch out for.

Recommended Mold Components for Import

If you’re aiming to generate good profit margins while maintaining quality, consider starting with the following:

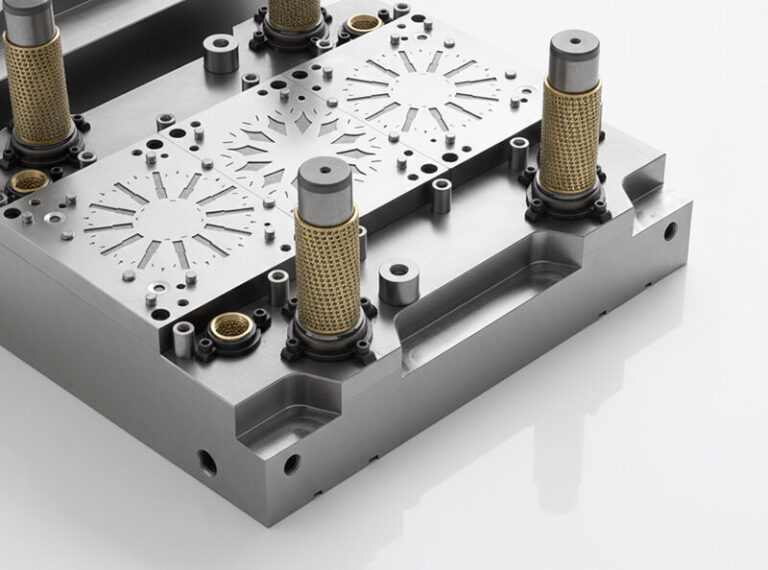

1. Guide Pillars & Guide Bushings

These are fundamental alignment parts used in both plastic molds and stamping dies. They are frequently replaced in production, ensuring consistent demand.

2. Ejector Pins (Straight & Step Types)

Small but essential, ejector pins are used in almost every plastic mold. Their lightweight and standardized specifications make them ideal for bulk import.

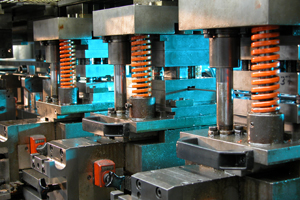

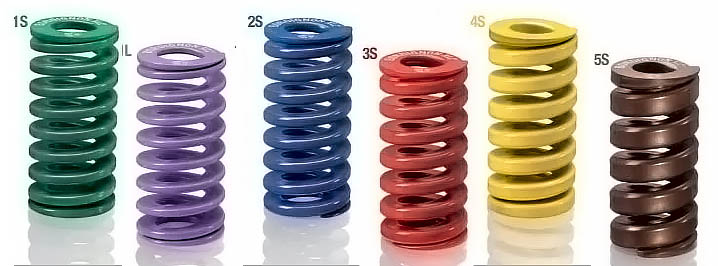

3. Die Springs (ISO 10243 / JIS)

Compression springs, particularly gas springs and high-force die springs, are widely used in stamping dies and automation equipment.

4. Locating Rings, Support Pillars & Sprue Bushings

These standard mold components are often outsourced by mold makers to save time and cost. They are relatively easy to stock and resell.

5. Customized Core Inserts or Mold Parts (OEM)

For more advanced markets, customized core inserts or mold bases designed according to CAD drawings can bring higher returns, especially when offering localized support.

What Global Buyers Should Consider When Sourcing

To ensure a successful import experience, we recommend checking the following:

- Material Certification & Hardness

Verify the steel grade (e.g. SKD61, H13, 1.2344) and request heat treatment reports. The same material label from different factories may vary significantly in performance. - Dimensional Tolerances

Tight tolerance is crucial for direct assembly. Ask for inspection reports or confirm whether the supplier follows standards like MISUMI, HASCO, or DIN. - Packaging & Rust Protection

Parts should be clean, oil-protected, and packaged securely to avoid corrosion or damage during international shipping.

Common Mistakes to Avoid

Many new importers fall into similar traps when sourcing mold components. Here are three we frequently observe:

- Assuming All “Standard Parts” Are the Same

Not all suppliers strictly follow international standards. Always verify specs and request samples for comparison. - Neglecting Minimum Order Requirements

To maintain competitive prices, factories often set MOQs. Planning bulk purchases or consolidating SKUs can reduce unit costs. - Focusing Solely on Price

Low prices may lead to hidden costs in the form of poor tolerances, surface issues, or reworking costs. Always balance cost with quality.

Final Thoughts

Importing mold components from China can be a highly profitable business — but it requires careful supplier evaluation and a clear understanding of component standards.

Our factory supports OEM production based on your designs or samples, and we offer global shipping with export-grade packaging. Whether you’re sourcing for resale or internal production, we’re happy to provide sample support and technical guidance to help you get started.