Why are the demands for precision mold components so high in production processes?

The stringent requirements for precision mold components in production processes stem from several key factors:

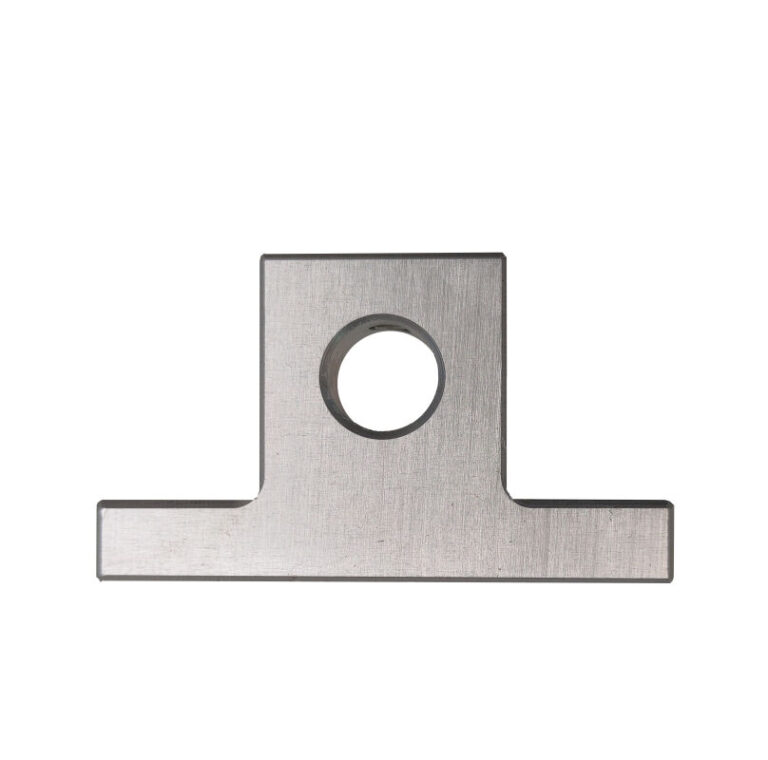

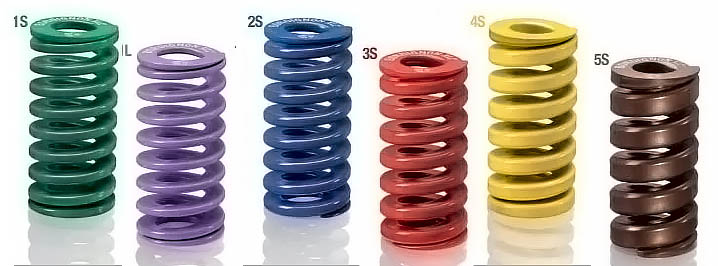

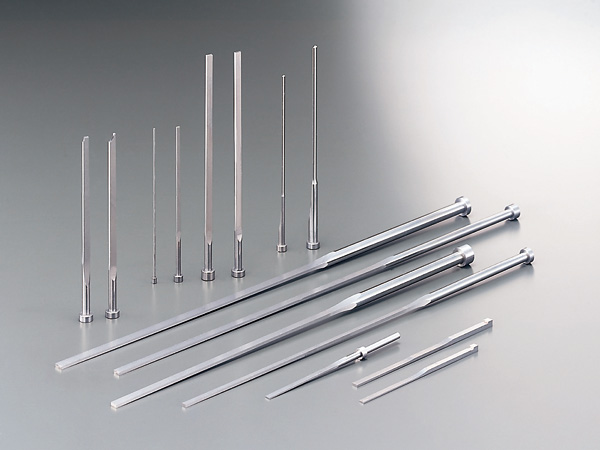

- Harsh working conditions: Precision mold components often operate in demanding environments. Therefore, it’s crucial to employ high-precision machining methods to ensure their longevity and performance.

- Strength and toughness: Enhancing the strength and toughness of precision mold components is essential. This not only prevents brittleness during operation but also ensures optimal efficiency.

- Material selection: Proper material selection is critical, especially when components are exposed to high temperatures. Prolonged exposure can degrade hardness and strength, leading to premature wear or failure.

In conclusion, the high demands on the production process of precision mold components are driven by the need to reinforce their appearance for specific applications. Additionally, their superior precision and performance compared to ordinary mold components require meticulous attention to both production processes and material selection.