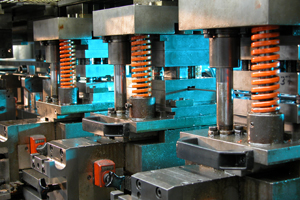

Why Is Slug Pulling More Common in High-Speed Stamping, and How to Solve It?

Slug pulling occurs when the punch, during its return stroke, unintentionally lifts the slug (the blanked-out piece) back up from the die hole. This can lead to die damage, punch breakage, and part defects—especially in high-speed operations (400–3000 SPM), where the risk is significantly higher.

Common Causes of Slug Pulling in High-Speed Stamping

1. Vacuum effect due to punch speed

The high-speed motion of the punch creates a sudden negative pressure (vacuum) in the die hole. This can “suck” the slug back up with the punch.

2. Incomplete slug drop before punch return

At high speeds, the slug may not fully fall before the punch begins to retract, increasing the chance it gets picked up again.

3. Inadequate or misapplied lubrication

Lubricants can be blown away by compressed air or machine vibration, resulting in dry contact and slug adhesion to the punch.

4. Poor die clearance or geometry

Insufficient die clearance or lack of a tapered die hole can cause slugs to stick instead of falling away cleanly.

Solutions to Prevent Slug Pulling

1. Anti-slug punch design

Use punches with a small step or reverse taper at the tip to mechanically push the slug down during retraction.

2. Air blow ejection system

Timed air bursts through die holes help dislodge and eject slugs during punch return. Requires precise control to avoid interference.

3. Tapered or vacuum-assisted die holes

Tapered die holes or suction channels help slugs fall away naturally without sticking or bouncing.

4. Optimized lubrication

Use micro-spray or mist systems to maintain lubrication without excess buildup. Select oils with strong adhesion and impact resistance.

5. Surface treatments and coatings

Coatings like DLC or TiCN reduce adhesion between the punch and the slug, lowering the chance of pull-back.

6. Improved die venting

Adding vent holes or slots in the die relieves air pressure and helps slugs drop freely.

Summary

Slug pulling is the result of vacuum, friction, and poor slug control. The best approach is a combination of punch design, proper lubrication, air or vacuum assistance, and die geometry optimization.

If you need custom-made high-performance punches designed to prevent slug pulling, feel free to contact us.