Mounting Brackets for Gas Springs: Essential Components for Optimal Performance

Gas springs, often filled with nitrogen gas, are vital in numerous industrial and mechanical applications, providing a reliable and efficient means of controlling motion and force. However, their performance is significantly influenced by the mounting brackets that secure them in place. Mounting brackets for gas springs are crucial for ensuring stability, durability, and functionality. In this article, we will explore the importance of these brackets, the types available, their applications, and best practices for selecting and installing them, focusing specifically on nitrogen gas spring plates.

Understanding the Importance of Mounting Brackets

Mounting brackets serve as the foundational support for gas springs, ensuring they are securely fastened to the application surfaces. Properly installed brackets prevent unwanted movement and misalignment, which could lead to operational failures and safety hazards. The efficiency and longevity of gas springs, including nitrogen gas springs, heavily rely on these mounting components.

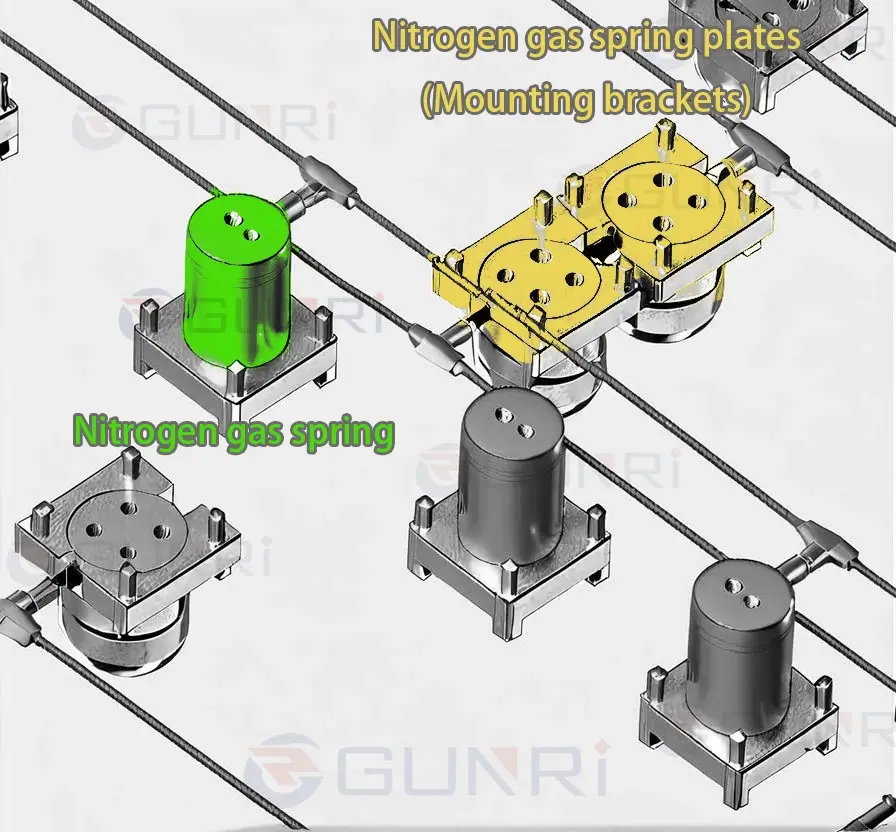

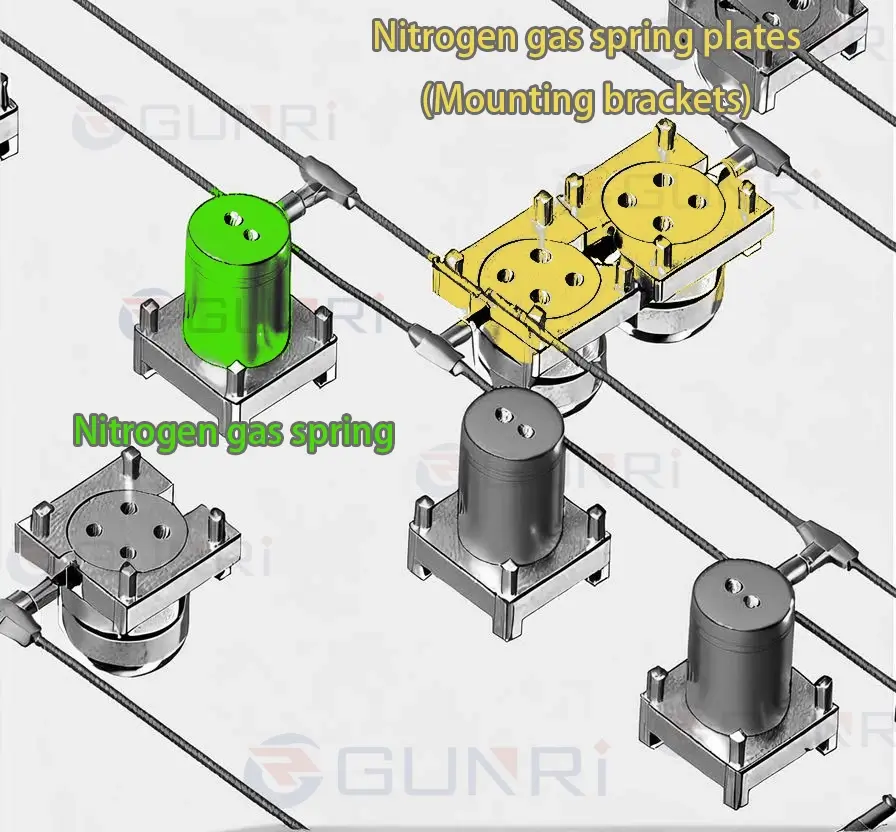

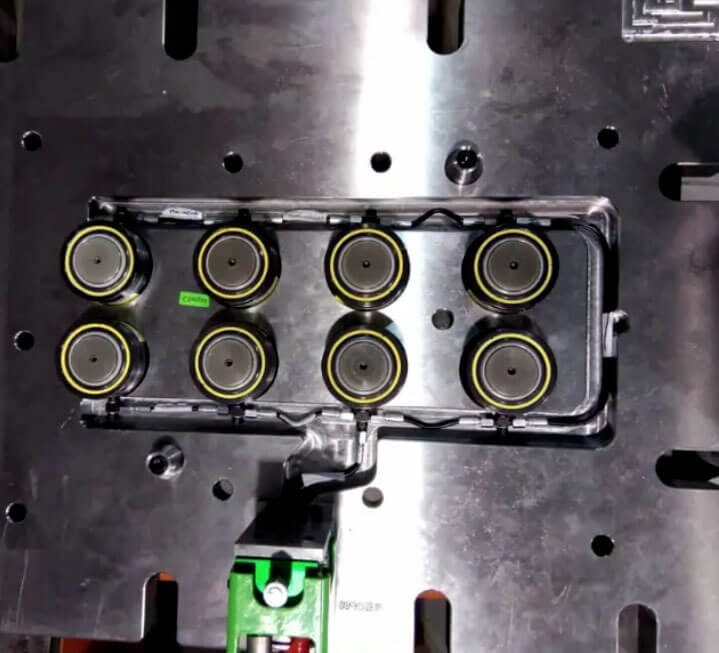

Product Overview: Nitrogen Gas Spring Plate

Compact Design and Space Efficiency

Nitrogen gas spring plates are designed to be compact, occupying minimal space while providing robust support. This space-saving design ensures efficient fastening without compromising the integrity of the gas spring system. The small volume of these plates makes them ideal for applications where space is limited but performance cannot be compromised.

Precise Installation for Stability

Strict installation tolerances are maintained to ensure the stable operation of nitrogen gas springs. The precise alignment facilitated by these mounting brackets minimizes the risk of misalignment and enhances the overall functionality of the gas spring. Accurate installation is essential for maintaining the operational efficiency and safety of the system.

Rich Model Availability

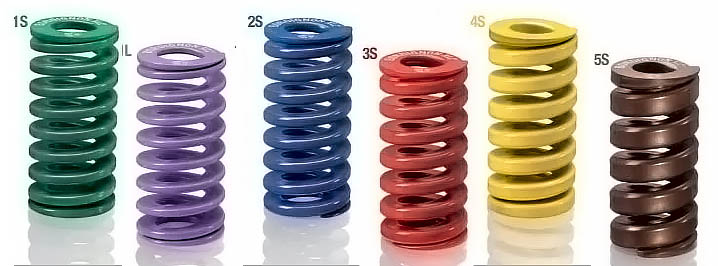

Nitrogen gas spring plates come in a variety of models, covering a full range of specifications to meet diverse application needs. Some of the available models include:

- FFC38

- FFCA75

- FFCB63

- FCM19

- FFS63

This extensive model range ensures that there is a suitable mounting solution for every type of nitrogen gas spring, regardless of the application requirements.

Installation Method

The top groove fixed type is a common installation method for nitrogen gas spring plates. This method involves securing the plate in the upper groove of the nitrogen gas spring. The top groove design provides a secure and stable attachment point, ensuring that the gas spring remains firmly in place during operation.

Use Precautions

Preventing Danger

Handling nitrogen gas springs requires strict adherence to safety protocols to prevent accidents. It is imperative to avoid actions that could compromise the integrity of the gas spring.

- Prohibited Actions: Do not disassemble, weld, melt, heat, or modify the nitrogen gas spring. These actions can lead to the release of high-pressure nitrogen gas, posing significant safety risks. There is a potential for parts to pop out due to the high pressure inside the gas spring, which could result in serious injury.

Operating Environment Temperature

Nitrogen gas springs should be used within the recommended room temperature range. If the surface temperature exceeds 80°C, there is a risk of explosion or seal deterioration, which can cause leakage. It is crucial to monitor the operating environment temperature to ensure the safe and effective use of the gas spring.

Heat Dissipation and Gap Maintenance

To prevent overheating and ensure proper heat dissipation, it is necessary to maintain a gap of at least 2mm on one side of the gas spring. This gap helps in preventing contact with the installation hole and allows for adequate cooling, thereby reducing the risk of heat-related issues.

Applications of Mounting Brackets for Gas Springs

Mounting brackets for gas springs are used in a wide range of industries, including automotive, aerospace, medical, and industrial machinery. Their versatility and reliability make them indispensable components in various applications.

Automotive Industry

In the automotive sector, gas springs are commonly used in hood supports, trunk lids, and convertible tops. Mounting brackets ensure these components function smoothly, providing ease of access and safety.

Aerospace Industry

The aerospace industry demands high precision and reliability. Gas springs in aircraft seating and cargo doors rely on robust mounting brackets to withstand extreme conditions and ensure passenger safety.

Medical Equipment

Medical equipment, such as hospital beds and examination tables, utilize gas springs for adjustable movements. Mounting brackets play a crucial role in ensuring smooth and controlled motion, enhancing patient comfort and care.

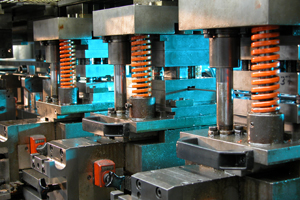

Industrial Machinery

In industrial settings, gas springs are used in machinery covers, access panels, and ergonomic equipment. Durable mounting brackets are essential to maintain operational efficiency and worker safety.

Selecting the Right Mounting Brackets

Choosing the appropriate mounting brackets is paramount to ensuring the optimal performance of gas springs. Consider the following factors when selecting mounting brackets:

Load Capacity

Ensure the mounting bracket can support the load exerted by the gas spring. Overloading a bracket can lead to failure and pose safety risks.

Material and Corrosion Resistance

Mounting brackets should be made from high-quality materials that resist corrosion and wear. Stainless steel and aluminum are popular choices due to their durability and resistance to harsh environments.

Compatibility

The bracket must be compatible with the gas spring’s size, type, and application. Consult the manufacturer’s specifications to ensure proper fit and function.

Best Practices for Installing Mounting Brackets

Proper installation is critical to the performance and longevity of gas springs and their mounting brackets. Follow these best practices to ensure successful installation:

Aligning Brackets Correctly

Ensure that the brackets are aligned accurately to prevent undue stress on the gas spring and mounting points. Misalignment can lead to premature wear and failure.

Secure Fastening

Use appropriate fasteners and ensure they are tightened to the manufacturer’s specifications. Loose fittings can cause instability and potential detachment.

Regular Maintenance

Inspect mounting brackets regularly for signs of wear, corrosion, or damage. Replace any compromised components promptly to maintain the system’s integrity and safety.

Innovations in Mounting Brackets for Gas Springs

Advancements in technology have led to innovative designs in mounting brackets, enhancing their functionality and reliability.

Quick-Release Mechanisms

Quick-release brackets allow for rapid attachment and detachment of gas springs, facilitating easy maintenance and replacement. These brackets are particularly useful in applications requiring frequent adjustments.

Anti-Vibration Features

To minimize the impact of vibrations and shocks, some mounting brackets are equipped with anti-vibration features. These brackets are essential in applications where stability and noise reduction are critical.

Customizable Solutions

Manufacturers now offer customizable mounting brackets tailored to specific application requirements. Custom brackets ensure optimal performance by precisely matching the gas spring’s specifications and operational needs.

Conclusion

Mounting brackets for gas springs, including nitrogen gas spring plates, are vital components that significantly influence the performance and reliability of gas springs in various applications. By understanding the types, applications, and best practices for selecting and installing these brackets, we can ensure that our systems operate smoothly and safely. Investing in high-quality mounting brackets is a crucial step toward achieving optimal functionality and longevity of gas springs, ultimately enhancing the overall efficiency and safety of our operations.

For businesses seeking reliable and high-quality mounting brackets for gas springs, GUNRI offers a comprehensive range of products tailored to meet diverse application needs. Whether you require nitrogen gas spring plates or other mounting solutions, GUNRI’s expertise and commitment to excellence ensure you receive the best products for your specific requirements.

Contact GUNRI today to learn more about our offerings and how we can support your operational needs.